A Storage Bin Inspection with the Elios 3 at a mine

A Storage Bin Inspection With The Elios 3 At A Mine

How can drones make storage bin inspections safer and more efficient? MIS Aero showcased the advantages of using the Elios 3 drone to a major mining client in Oman, proving its value in real-world conditions.

Key Benefits at a Glance

|

Speed Using the Elios 3 cut inspection time from 15 days down to just 4. This drastic improvement allowed for quicker decision-making and reduced operational delays. |

Safety The Elios 3 eliminated the need for personnel to enter confined spaces, avoiding risks like high dust exposure and working at height. It kept the team safe while still collecting critical data. |

|

Data Quality MIS Aero provided full 3D models of the storage bins with detailed points of interest. This made it easier for engineers to plan maintenance and identify issues accurately. |

Access The Elios 3 offered flexible access to every part of the storage bins, even in tight or dusty areas. Its maneuverability gave pilots confidence during complex inspections. |

Safe mining operations involve not only the mine itself but also the surrounding infrastructure, such as storage bins and crushers. Regular maintenance is essential for both safety and efficiency. However, inspecting large storage bins can be difficult due to height, dust, and limited visibility.

A mining company in Oman faced these challenges when inspecting their storage bins. They needed a safer, faster way to check for damage to the polyethylene lining inside the tanks. Previously, inspectors had to use rope access, which was time-consuming and dangerous. They wanted a better solution that could reduce inspection time and improve safety.

The storage bins, standing at 40 meters, present significant challenges for traditional inspections.

The storage bins, standing at 40 meters, present significant challenges for traditional inspections.

What Is a Standard Storage Bin Inspection?

Traditionally, internal inspections of storage bins involved manually entering the structure using ropes. This method posed serious risks, including exposure to dust, high-altitude work, and confined space hazards. Inspections could take up to 15 days, causing delays and increasing costs.

With the goal of improving safety and efficiency, the mine sought a new approach. That’s where MIS Aero came in, bringing in the Elios 3 drone—a powerful tool designed for confined space inspections.

The Elios 3 flying back down to the team after completing an inspection.

The Elios 3 flying back down to the team after completing an inspection.

Drone Inspections with the Elios 3

MIS Aero, the sole owner of the Elios 3 in Oman, partnered with the mine to implement a safer and faster inspection process. The Elios 3 is equipped with LiDAR and visual imaging, making it ideal for navigating dusty and complex environments.

They planned custom flight paths to cover all seven 40-meter-tall storage bins. By using multiple entry points and range extenders, they avoided the need for human entry into the bins. The team also worked closely with the mine staff to identify potential obstacles, ensuring the drone’s safe operation.

The pilot and inspector review the data collected during the flight.

The pilot and inspector review the data collected during the flight.

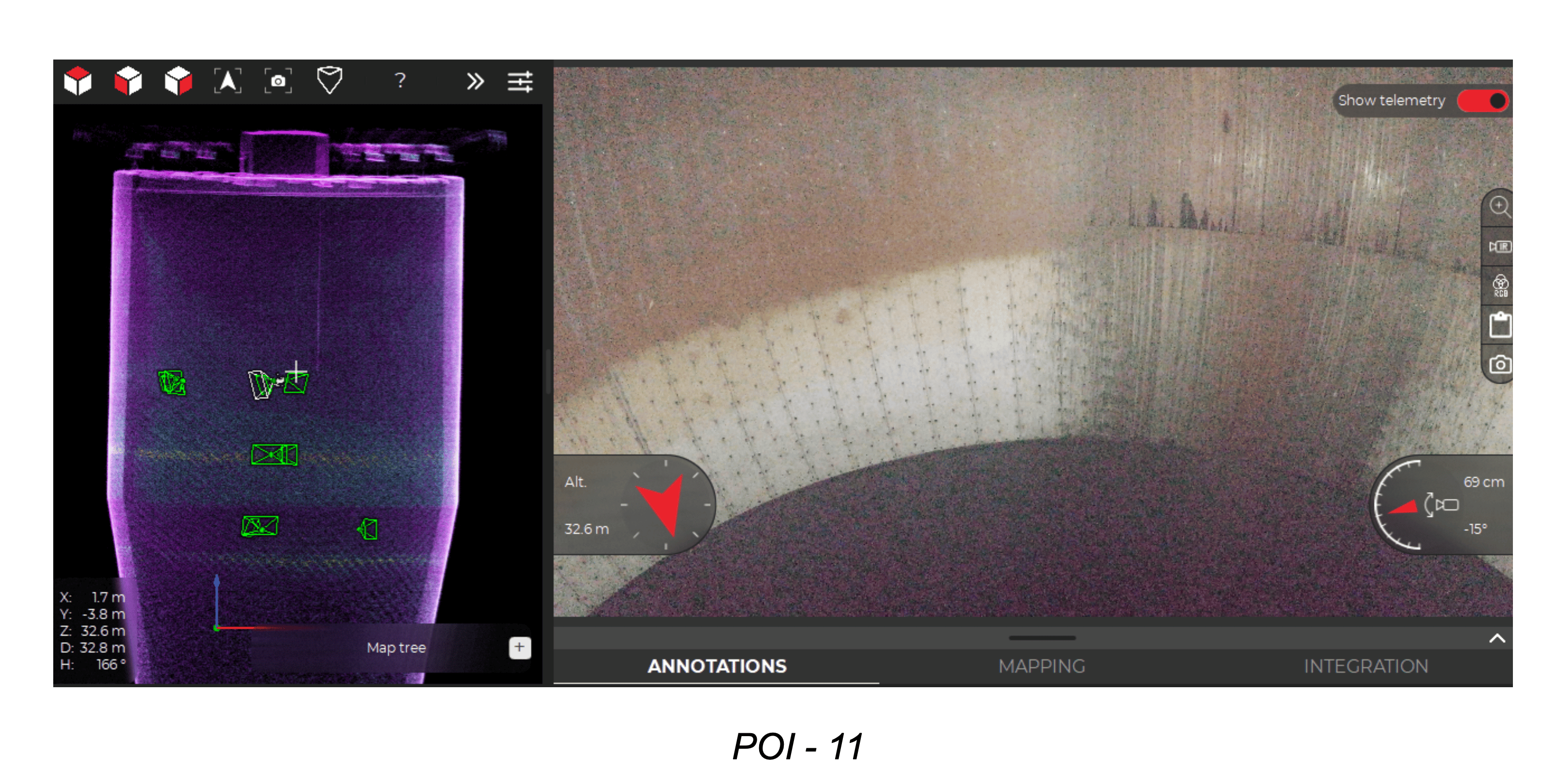

After the flights, the data was processed using Inspector 4 software to generate a detailed report. The client was impressed by the accuracy and clarity of the results, especially the geolocation of points of interest within the 3D model. This helped them plan maintenance more efficiently and improved communication across teams.

Setting a New Standard for Storage Bin Inspections

This project marked a major milestone for the mine and for MIS Aero. By adopting the Elios 3, they significantly reduced inspection time and risk, setting a new benchmark for safety and efficiency in the region.

The LiDAR scan includes points of interest (POI) identified by inspectors during the flight, allowing precise location tracking between the scan and photos taken by the Elios 3.

This successful project has opened the door for more clients to adopt drone-based inspections in Oman. It shows how innovative technology can transform traditional practices, making mining safer, faster, and more reliable. As MIS Aero continues to push the boundaries of what's possible, the future of mining inspections looks brighter than ever.

Shandong Vio Machinery co.,ltd. , https://www.shantui-xcmgparts.com