Motor Sizing & Selection Example: Variable Speed Belt Conveyor

Many motor manufacturers provide motor sizing tools to assist with product selection, but if you’re unfamiliar with how to use them effectively, you may end up paying more in the long run. A proper motor sizing is crucial to calculating the essential requirements—torque, speed, and inertia—for a specific application. Once these values are determined, the next step is selecting the appropriate motor size to avoid over-sizing or under-sizing issues.

This post explains how to utilize a motor sizing tool to calculate these key values and how to apply them to select a motor for a variable-speed belt conveyor. Understanding these steps ensures that you choose the right motor for your application, saving both time and resources.

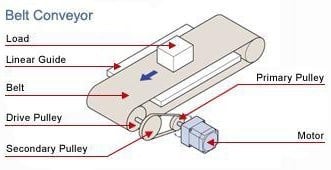

### What is a Belt Conveyor?

Belt conveyors use pulleys and belts to convert rotational motion into linear motion, enabling the movement of a load along the belt. Linear guides often support the load, while the motor can connect to the drive pulley through a combination of primary and secondary pulleys, adding an external gear ratio.

To better understand the components involved, take a look at the image below showcasing a belt conveyor motor sizing tool:

In order to determine the inertia, speed, and torque required by the motor, a series of calculations is necessary. Many motor manufacturers employ a motor sizing calculator where users can input values to generate the desired results.

### Using the Motor Sizing Example

Let’s explore an example of sizing a motor for a horizontal belt conveyor designed to move a load weighing 100 lbs at speeds ranging from 12 to 24 inches per second.

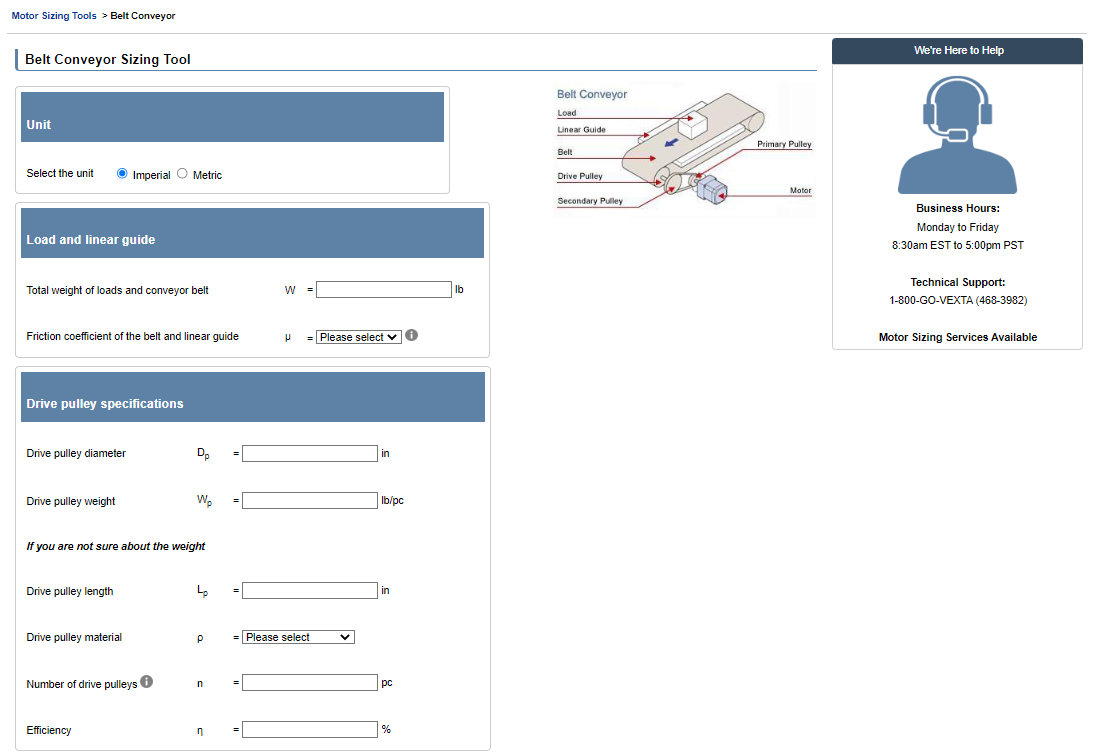

When starting the process, you’ll encounter a form like the one shown below:

Here are the parameters you’ll need to fill out. Remember, the accuracy of the results depends entirely on the precision of the inputs, so try to avoid making overly rough estimates.

### Input Parameters

| **Parameters** | **Values** |

|-------------------------------------------|--------------------------------|

| Total weight of loads and conveyor belt | 100 lbs |

| Friction coefficient of belt and guide | 0.1 |

| Drive pulley diameter | 12 inches |

| Drive pulley weight | 1 lb |

| Total number of pulleys | 4 |

| Mechanical efficiency | 90% |

| External force | 0 lb |

| External gear ratio | None |

| Mechanism angle | 0° |

| Hold load after power off | No |

| Hold load only when powered on | Yes |

| Required speed | 12~24"/sec |

| Acceleration/Deceleration time | 1 second |

| Stopping accuracy | 0.25 inches |

| Safety factor | 2 |

---

#### Step-by-Step Guide

1. **Select the Unit**: First, choose whether to use imperial or metric units. Since the load is given in pounds, we’ve selected “Imperial.â€

2. **Input Load and Friction Coefficient**: Enter the total weight of the loads and the friction coefficient of the belt and linear guide.

3. **Drive Pulley Specifications**: Provide details about the drive pulley, including its diameter and weight, ensuring the correct number of pulleys is accounted for.

4. **Consider External Forces**: Add any external forces like spring loads that may oppose the movement.

5. **External Gear Ratio**: If applicable, input any external pulleys or gear ratios. For direct coupling, leave these fields blank.

6. **Mechanism Angle**: Specify the conveyor’s angle in degrees. This conveyor is horizontal, so we’ve entered 0°.

7. **Other Requirements**: List any additional requirements such as electromagnetic brakes or electrical holding torque.

8. **Operating Conditions**: For variable speed requirements, specify low speed (V1) and top speed (V2) in inches per second, along with the acceleration/deceleration time (t1).

9. **Stopping Accuracy**: Input the required stopping accuracy, converting the linear unit “in†to “degrees.â€

10. **Safety Factor**: Use a larger safety factor if unsure about the input values to account for unforeseen variables.

Finally, click the “Calculate†button to view your sizing results.

---

### Viewing the Sizing Results

After completing the above steps, you’ll receive a summary of the motor’s primary requirements:

| **Motor Requirements** |

|---------------------------------------|

| Load Inertia | 58,752 oz-in² |

| Required Speed | 19.1~38.2 RPM |

| Required Torque | 209.4 lb-in |

With these results, you can now search for a suitable motor using the “Search by Specification†tool.

---

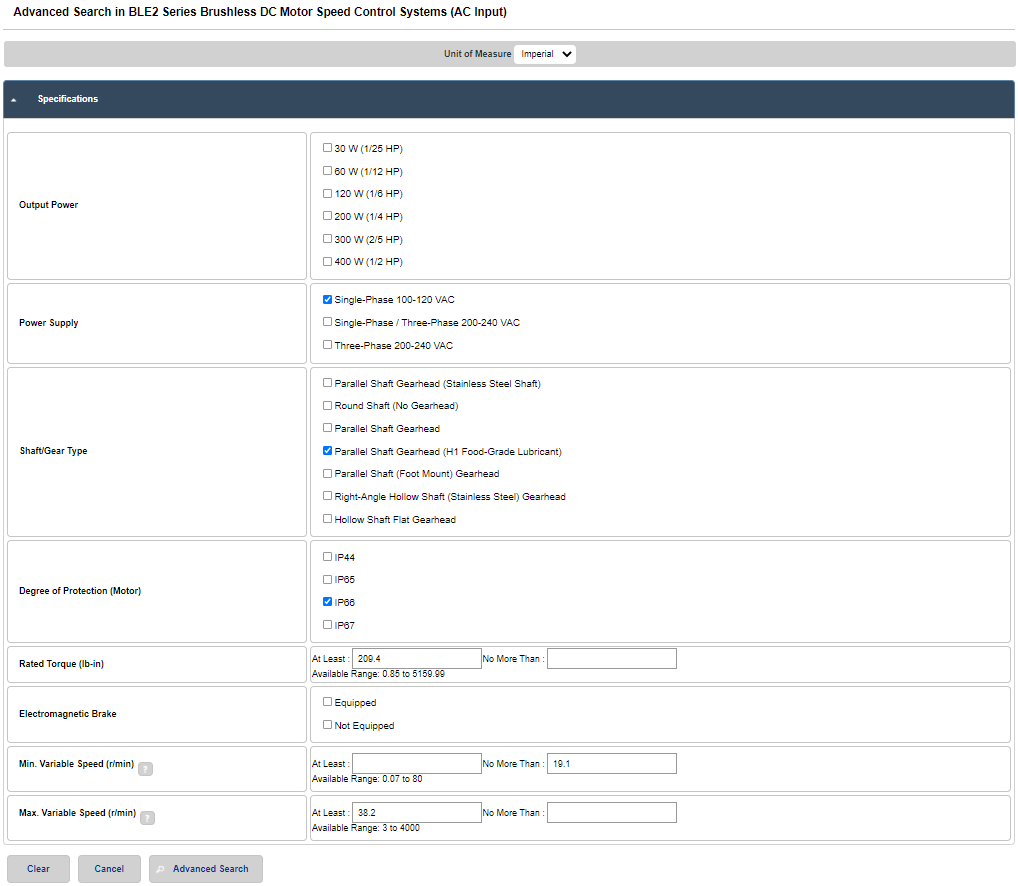

### Selecting the Right Brushless Motor

Brushless motors are particularly well-suited for continuous-duty variable-speed conveyors due to their performance, size, and efficiency characteristics. They also offer a variety of driver functions and gear options.

To select the best brushless motor, follow these steps:

1. Navigate to the motor type page on our website.

2. Use the “Search by Specification†tool to input your sizing results.

3. Filter your search based on parameters such as output power, torque, variable speed range, gearhead type, and IP rating.

Here’s an example of the search criteria used:

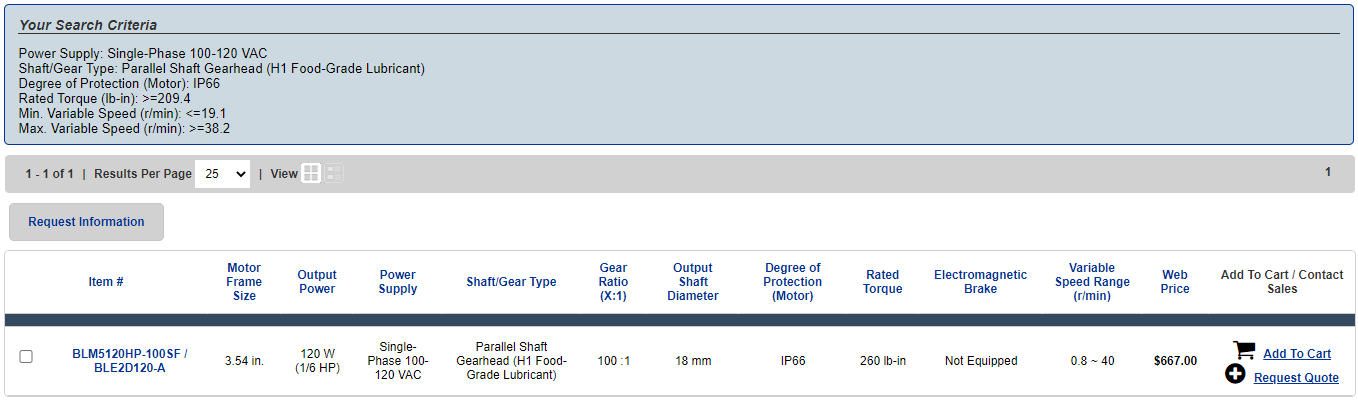

Once the search is complete, you’ll receive a list of products that meet your requirements:

### Evaluating the Selected Motor

The recommended motor, the [BLM5120HP-100SF / BLE2D120A], offers 260 lb-in of torque and a variable speed range of 0.8~40 RPM. It can handle up to 66,000 oz-in² of load inertia, making it ideal for demanding applications. Additionally, it features H1 food-grade grease and an IP66 rating, perfect for conveyor systems that require frequent washdowns.

---

### Summary

Choosing the right motor for your application is critical to avoiding costly redesigns or delays. By understanding how to use motor sizing tools effectively, you ensure that your design meets all primary requirements while considering additional factors such as motor type, size, gear ratio, IP rating, and product features.

If multiple options meet your primary requirements, further evaluate their features and functions to pick the best fit for your application and budget.

Prefer assistance with motor sizing? Our team of experienced engineers is ready to help!

---

Looking for more guidance? Try the [Belt Conveyor Sizing Tool](http://bsg-i.nbxc.com/blog/b7fabcc995c7de50bdf32dc2d4343d62.png) or contact us for personalized support.

We are China External Spring Lotion Pump,Lotion Pump With Spring Outside,Outer Spring Lotion Pump manufacturer, high quality control

External Spring Lotion Pump is one type of lotion pump,with smooth and ribbed closure,size 24/410 28/410 ,the metal spring won't touch the liquid.

Various style of dispensing heads ,designed for comfortable and easy to use.

Used for hair care,body lotion ,shampoo ,soap disinfectant

External Spring Lotion Pump,Lotion Pump With Spring Outside,Outer Spring Lotion Pump,Lotion Pump Spring Outside

NINGBO CRETE PLASTIC CO.,LTD , https://www.crete-sprayer.com