Motor Sizing & Selection Example: Variable Speed Belt Conveyor

Many motor manufacturers provide a motor sizing tool to assist in product selection, but if you're unsure of how to use it, you might end up regretting it in the long run. Proper motor sizing is essential to determine the motor’s primary requirements for a specific application: torque, speed, and inertia. After calculating these values, the next step is product selection, which involves choosing a particular motor size to prevent over-sizing or under-sizing issues. This article will walk you through using a motor sizing tool to calculate these values and selecting a motor for a variable speed belt conveyor.

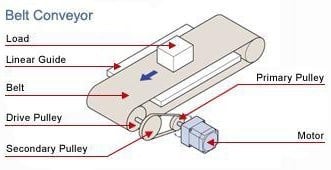

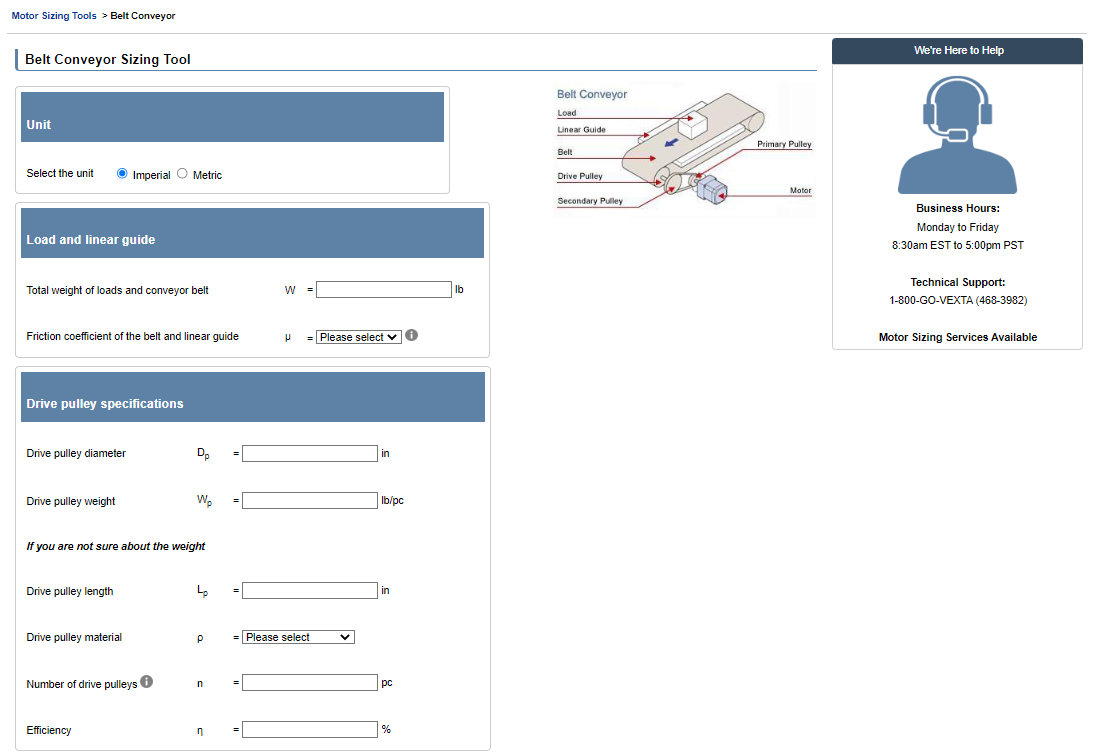

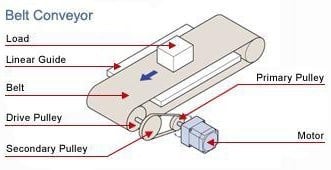

A belt conveyor utilizes pulleys and belts to convert rotational motion into linear motion, allowing the movement of a load across its belt. There might be a linear guide supporting the load. The motor can be connected to the drive pulley via a combination of primary and secondary pulleys, adding an external gear ratio.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '0ad55899-1a85-4603-9336-82939da22c69', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '0ad55899-1a85-4603-9336-82939da22c69', {"useNewLoader":"true","region":"na1"});

|

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '68e50b47-7732-4a9c-b51c-97bc3a36be36', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '68e50b47-7732-4a9c-b51c-97bc3a36be36', {"useNewLoader":"true","region":"na1"});

|

To determine the inertia, speed, and torque needed by the motor, a series of calculations must be performed. Many motor manufacturers use some form of a motor sizing calculator where you can input values to obtain your results.

| Motor Sizing Example | Variable Speed Belt Conveyor |

In the following sections, I will explain how to use our

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '4ba7e5ef-a979-4f77-9ab9-9d259550b0cd', {"useNewLoader":"true","region":"na1"});

for a horizontal belt conveyor that needs to move a load of 100 lbs at speeds between 12 and 24 inches per second.

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '4ba7e5ef-a979-4f77-9ab9-9d259550b0cd', {"useNewLoader":"true","region":"na1"});

for a horizontal belt conveyor that needs to move a load of 100 lbs at speeds between 12 and 24 inches per second.

Here's what you see when you begin.

These are the parameters I need to enter into the motor sizing tool. Remember, the accuracy of the sizing results depends on the input values, so try not to guess too much.

| Parameters | Values |

| Total weight of loads and conveyor belt Friction coefficient of the belt and linear guide Drive pulley diameter Drive pulley weight Total number of pulleys Mechanical efficiency External force External gear ratio Mechanism angle Hold the load even after power is turned off Hold the load only when power is on Required speed Required acceleration/deceleration time Stopping accuracy Safety factor |

100 lbs 0.1 12 inches 1 lb/pc 4 total pulleys 90% 0 lb none 0° No yes 12~24"/sec 1 second 0.25 inches 2 |

First, select the "Unit". This will change the units on the motor sizing tool to imperial or metric. Since my load is in pounds, I chose "Imperial".

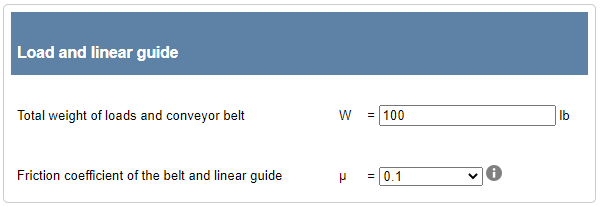

Input the values for "Total weight of loads and conveyor belt" and "Friction coefficient of the belt and linear guide". The belt weight is considered as part of the load.

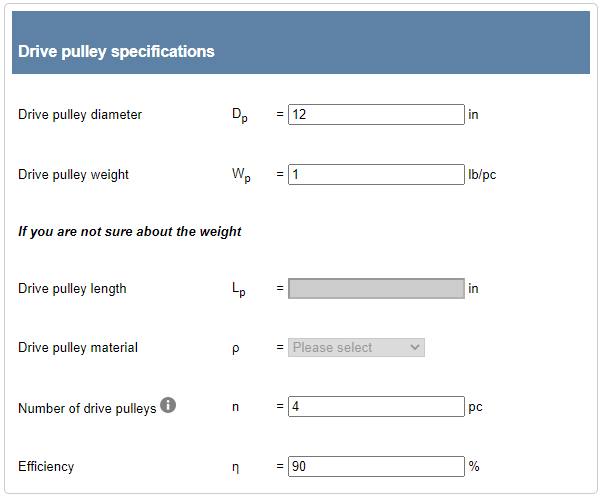

Next, input the "Drive pulley specifications". Ensure you input the correct number of pulleys.

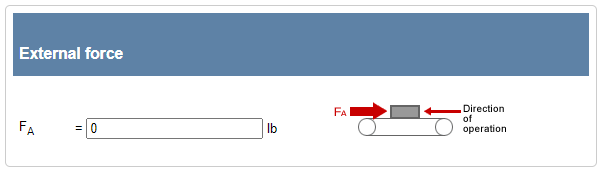

Remember to account for any "External force" or opposing forces, like a spring load.

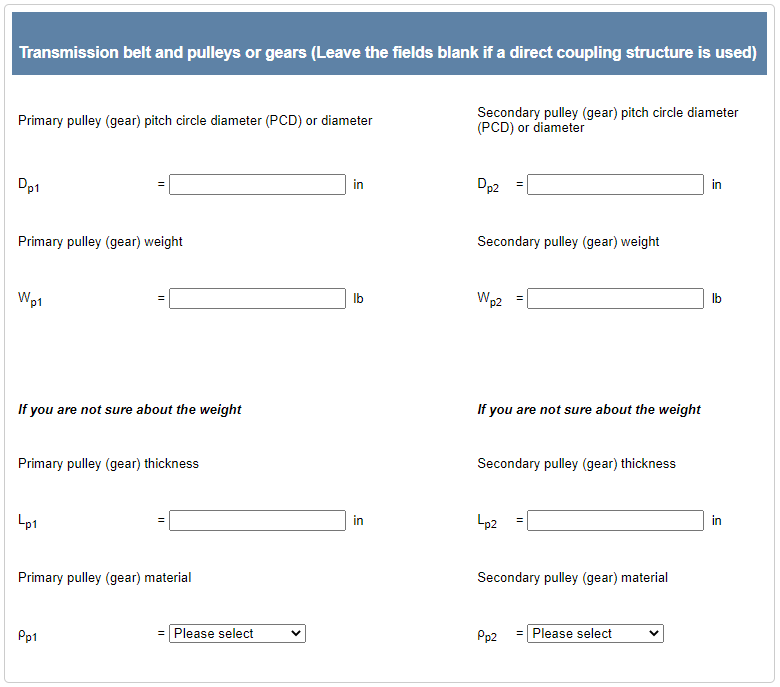

If you have any external pulleys or gear ratios, please input the information here. If you are directly coupling the motor to the drive pulley without any external pulleys, leave the fields blank.

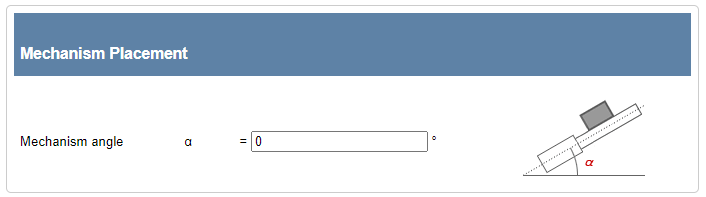

Input the "Mechanism angle" of the conveyor in degrees. This conveyor is horizontal, so 0° is entered.

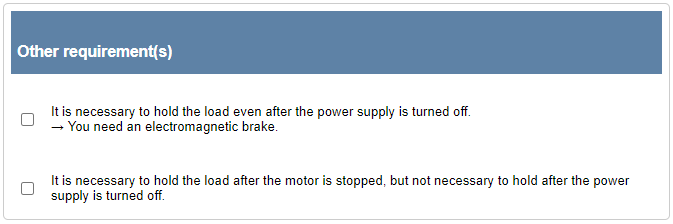

List any "Other requirement(s)" you may have, such as an electromagnetic brake or electrical holding torque.

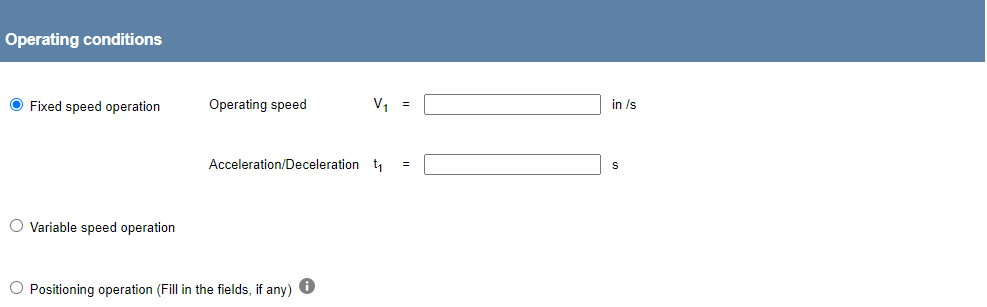

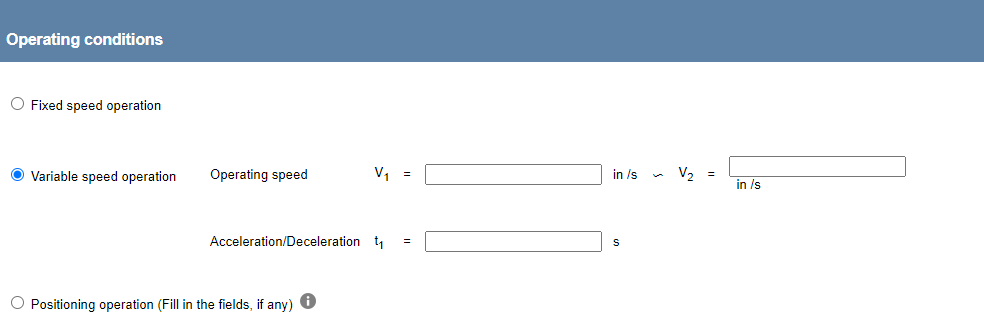

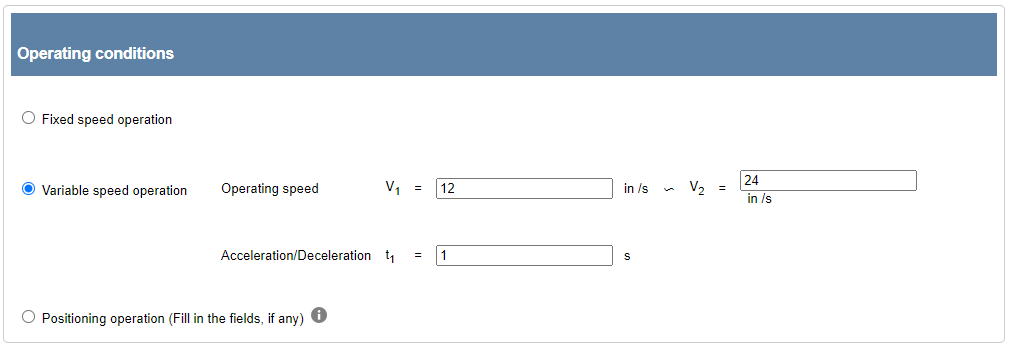

Input your "Operating conditions". For variable speed requirements, enter V1 (low speed) and V2 (top speed) in inches per second, then enter your acceleration/deceleration time (t1).

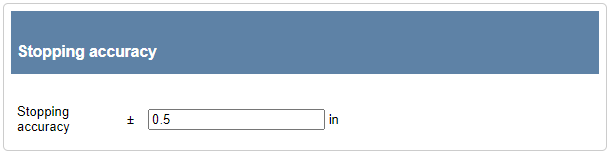

Enter the required "Stopping accuracy". This will convert the linear unit "in" to "degrees". This is more critical for positioning applications but is a required field.

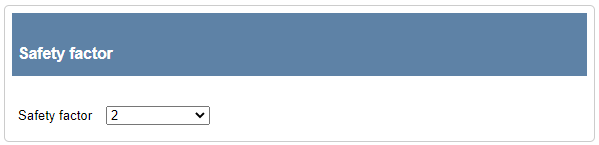

Last but not least, enter your "Safety factor". If you're unsure of your parameter values, use a larger safety factor. Always leave some room for other factors that might affect the motor requirements. For example, other friction in the system can increase the required torque.

To see your sizing results, click  at the bottom.

at the bottom.

| FYI |

Choosing different "operating conditions", such as "fixed speed operation", "variable speed operation", or "positioning operation" changes the input fields and calculations to accommodate different types of motors.

For example, here's how the input fields change for "fixed speed operation" and "variable speed operation".

|

OK back to the variable speed belt conveyor sizing.

| Motor Sizing Results | Variable Speed Belt Conveyor |

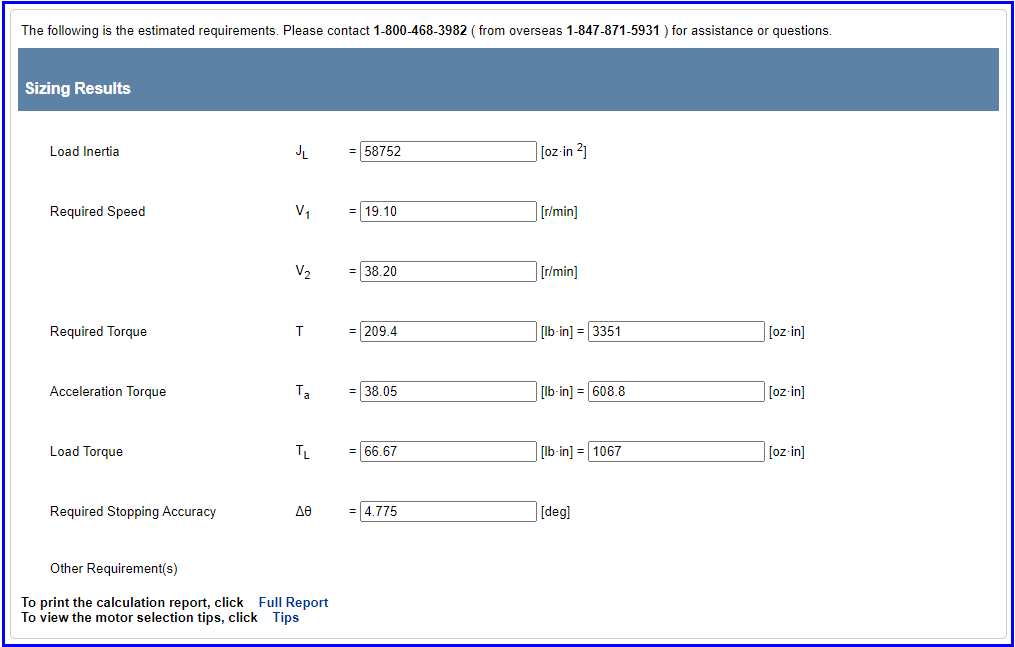

The motor sizing results are as follows:

We’ll need to find a motor that meets these primary requirements. We will skip "Required Stopping Accuracy" and "Other Requirement(s)" for this example.

|

Motor Requirements:

|

The easiest way to find a suitable motor is to use the "Search by Specification" tool for the specific type of motor. However, the "Search by Specification" tool is located on the overview pages for specific types of motors, so you need to select a type of motor first.

Use the  to find motors by specification(s), then input sizing results.

to find motors by specification(s), then input sizing results.

| Motor Selection Example | Variable Speed Belt Conveyor |

Brushless motors’ performance, size, and efficiency characteristics, combined with their unique driver functions and a variety of gear options, make them ideal for continuous-duty variable speed conveyors. Here's a guide that introduces the characteristics of all types of motors.

The following example shows how to use the sizing results to find the most suitable brushless motor and driver system.

Once you select the type of motor from our website navigation menu, please "Search by Specification" by using the sizing results you calculated.

Once you click "Search by Specification", then you can search by the following parameters:

- Output power

- Power supply

- Driver type

- Rated torque

- Min. variable speed

- Max. variable speed

- Shaft/gear type

- Gear ratio

- Output shaft type

- Degree of protection (IP rating)

- Electromagnetic brake

Since brushless motors require a driver, the power supply and driver type are for the dedicated driver that is required to control the brushless motor. Oriental Motor is focused on providing a complete solution rather than components.

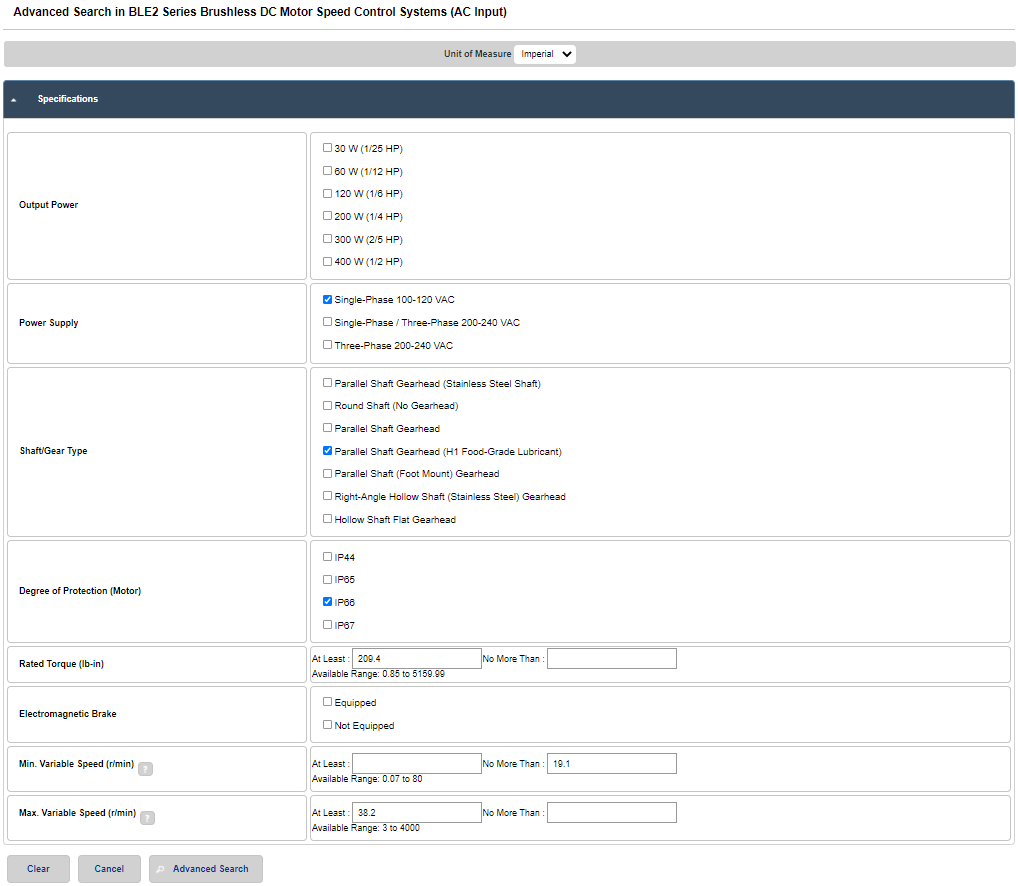

Here are the parameters I put in for the "Search by Specification". Notice that I only put in the parameters I know: power supply, driver type, torque, min. variable speed, max. variable speed, parallel shaft gearhead with H1 food grade grease, and IP66 rating.

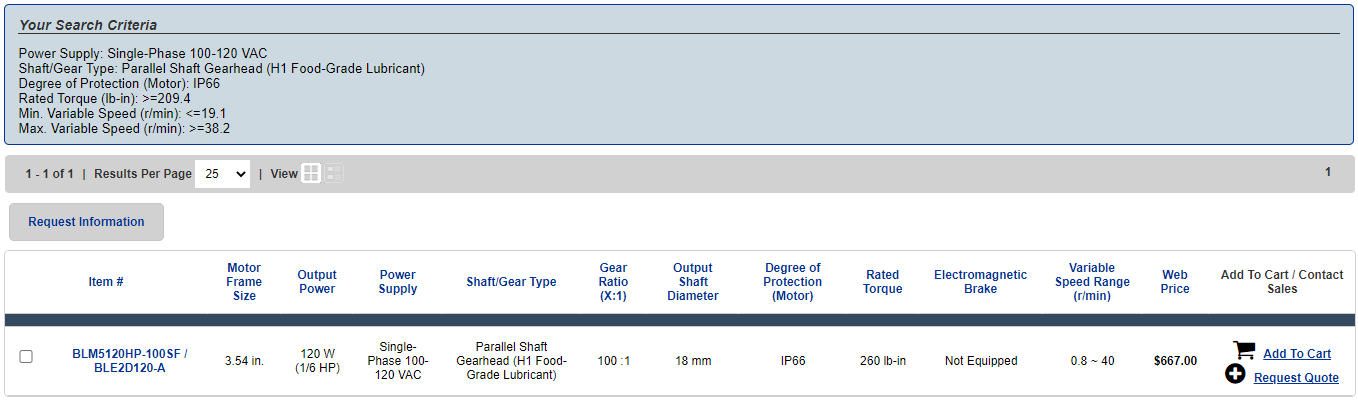

Once you click  , it will list the product(s) that satisfy these requirements.

, it will list the product(s) that satisfy these requirements.

How does this motor and driver [ BLM5120HP-100SF / BLE2D120A ] measure up?

This brushless gear motor offers 260 lb-in of torque and 0.8~40 RPM variable speed range. It can handle up to 66000 oz-in² of load inertia. These options also include H1 food grade grease and IP66 ratings, which are for conveyors that can come into contact with food and need periodic washdown.

| Summary |

|

Selecting the wrong product for the job could mean changing the BOM later or losing valuable time. Knowing how to use the sizing results is the first step to successful product selection. In addition to satisfying inertia, speed, and torque requirements, a machine designer also needs to consider the type of motor or actuator, the size of motor or actuator, the gear ratio or lead/pitch, the required power supply, the motor's IP rating as well as the product features and functions.

Pick the option that works best for your application (and budget). If there's more than one option that meets the primary requirements, look into the features and functions.

|

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '0ad55899-1a85-4603-9336-82939da22c69', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '0ad55899-1a85-4603-9336-82939da22c69', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'ac0d4f04-66f2-4541-881b-8617e3946737', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'ac0d4f04-66f2-4541-881b-8617e3946737', {"useNewLoader":"true","region":"na1"});

We are China Screw Down Lotion Pump,Plastic Lotion Pump manufacturer, high quality control

Screw down Lotion Pump is one type of lotion pump,with smooth and ribbed closure,size 20/410 24/410 24/415 28/400 28/410 28/415,output from 1ml to 4ml

Various style of dispensing heads ,designed for comfortable and easy to use.

Used for hair care,body lotion ,shampoo ,soap disinfectant

Screw Down Lotion Pump,Plastic Lotion Pump,Lotion Pump Dispenser,Screw Lotion Pump

NINGBO CRETE PLASTIC CO.,LTD , https://www.crete-sprayer.com