This is Part 1 of the Technical Manual Series on brushless motors, which explores the three primary types of brushless motors: inner rotor type, outer rotor type, and disk rotor type.

Brushless motors combine permanent magnets, windings, magnetic pole sensors, and a drive circuit to perform the function of a motor. They are highly efficient in terms of speed control and energy conservation. Unlike induction motors that require inverters and firing angle control for speed adjustment, these motors can operate across a wide range of speeds, from low-speed rotation to high-speed rotation. Since they use permanent magnets in the rotor and don’t require induced current like induction motors, brushless DC motors are compact, powerful, and efficient.

However, brushless DC motors were historically costly and had limited applications due to the need for permanent magnets in the rotor, magnetic pole sensors, and a specialized drive circuit.

In recent years, advancements in electronic components and increased integration of electronic parts have decreased both the cost and size of drive circuits. With the growing emphasis on energy conservation to combat global warming, brushless DC motors have become widely adopted in energy-efficient appliances like air conditioners, refrigerators, and washing machines. Additionally, they are utilized in vehicle drive motors and electric vehicle on-board motors. Their compact size and high output power make them suitable for various applications, including cooling fans for touchscreen computers, disk drive devices, and drones.

Given their minimal structural constraints, several designs have been developed. Here, we’ll explain the characteristics of the three most common configurations.

**Types of Brushless Motors**

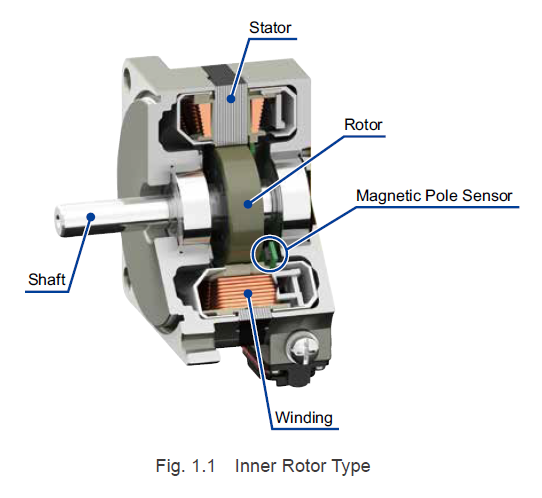

1. **Inner Rotor Type**

In the “inner rotor†type, the rotating component—the rotor—is placed inside the stator, with a segmented permanent magnet installed on the outer surface of the rotor. Due to its smaller rotor diameter and lower moment of inertia, it offers excellent acceleration and deceleration responsiveness. Additionally, since the stator is positioned close to the motor surface, there is effective heat dissipation, resulting in a compact motor with high output power.

This is the standard configuration for brushless motors and is used in a wide array of applications. Personally, I think they are ideal for space-saving or high-efficiency solutions in material handling, such as driving conveyor pulleys or AGV wheels.

[Insert video here]

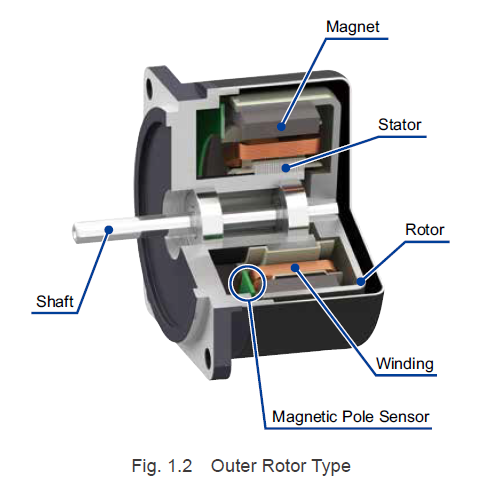

2. **Outer Rotor Type**

For the “outer rotor†type, the rotor is located outside the stator, with the permanent magnet positioned inside the rotor. The segmented permanent magnet is now installed on the inner surface of the rotor. The positions of the stator and the permanent magnets are reversed compared to the inner rotor type. A cup-shaped rotor isn’t ideal for agile movements because of its higher moment of inertia, resulting in poor acceleration and deceleration responsiveness. However, it still offers excellent speed stability.

Because the rotor diameter is larger, more magnets can be installed than in the inner rotor type, increasing the number of magnetic poles compared to the inner rotor type. This allows for high output power in a compact size. However, since the windings are located inside and heat dissipation is poor, the windings tend to overheat, limiting operating time. In drone motors that use an outer rotor type brushless motor, the rotor cup is equipped with ventilation holes, and the airflow generated by the propellers helps keep the windings cool.

Applications for the outer rotor type are more limited. The larger inertia of the rotor makes quick starts and stops more challenging. Poor heat dissipation also limits operational time. However, if the motor design considers heat ventilation, radiation, or cooling, the applications can extend to cooling fans and drones, for instance.

[Insert image of fan application]

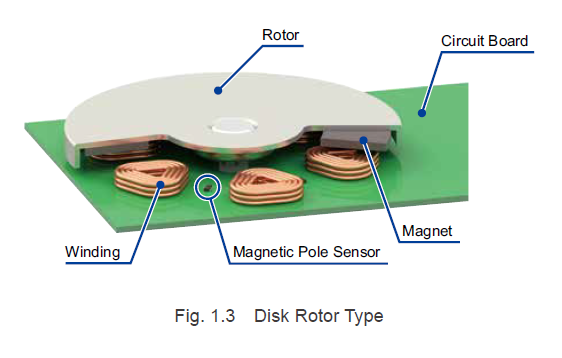

3. **Disk Rotor Type**

In the “disk rotor†type, the stator is formed by mounting the windings and magnetic pole sensors on the circuit board. The tabular permanent magnets are located on the rotor surface facing the stator, making this type of motor very thin. It is used to maintain a stable, fixed speed under light loads. There is no shaft, so the load is directly attached to the rotor.

This type of motor is commonly used in hard disk drives and disk drives for CDs, Blu-rays, and other media. However, it could extend to other applications where space is a constraint. Unfortunately, Oriental Motor doesn’t offer any disk rotor type brushless motors, but our brushless motors are designed to be shorter than competitors. We do offer flat type stepper motors (42/60 mm frame sizes) for positioning or indexing applications.

[Insert CTA for flat type stepper motors]

Oriental Motor’s inner rotor type brushless motors are designed for speed control applications. Reach out to our team to learn more!

[Insert video CTA]

In the next part of this Technical Manual – Brushless Motor Series, we will explore brushed DC motors. Subscribe to this blog to stay updated on future posts!

[Insert Next Post CTA]

[Insert CTA for AC and DC input brushless motor systems]

[Insert CTA for Oriental Motor’s brushless motor systems overview]

[Insert subscription CTA]

Tube Sheet

Tube sheet are usually made of a round flat plate with holes drilled into the plate to accommodate tubes in the exact location and pattern relative to each other. The tube sheet is used to support and isolate the tubes in the Shell And Tube Heat Exchanger.

A tube sheet is a plate used to support a tube in a shell and tube heat exchanger. The tubes are aligned in a parallel manner and are supported and held in place by the tube plate. A tube sheet is a round plate with holes in it so that the tube can fit through the opening. Tubes are usually made of round, flat metal sheets. Drill holes for pipe ends in precise locations and patterns relative to each other. The tube plate is made of the same range of materials as the pipe.

These are usually made of mild steel and vary in thickness according to fluid pressure. Depending on the final application (petrochemical, nuclear, oil and gas, etc.), the tubes can be clad in stainless steel or other superalloys, or even made entirely of stainless steel or superalloys.

Tube Sheet,Boiler Tube Sheet,Floating Tubesheet,Exchanger Tube Sheet

Guangdong Jiema Energy Saving Technology Co.,Ltd , https://www.jmheatexchanger.com