As part of our Technical Manual Series on brushless motors, today we’ll explore the three primary types of brushless motors: inner rotor, outer rotor, and disk rotor configurations. These motors are renowned for their exceptional speed control capabilities and energy efficiency. Unlike induction motors that rely on inverters and complex firing angle controls, brushless motors can operate across a broad spectrum of speeds, from low to high, without compromising performance. The use of permanent magnets in the rotor eliminates the need for inducing current into the rotor, making these motors compact, powerful, and highly efficient.

Traditionally, the cost and complexity of brushless motors were barriers to widespread adoption due to the necessity of permanent magnets, magnetic pole sensors, and specialized drive circuits. However, advancements in electronics and component integration have significantly reduced costs while shrinking the size of the drive circuits. With growing concerns over climate change, energy-efficient appliances like air conditioners, refrigerators, and washing machines are increasingly incorporating brushless motors. These motors also find applications in automotive sectors, including electric and hybrid vehicles, as well as in smaller gadgets like drones and cooling fans for touch-screen computers.

Given the flexibility in motor design, several configurations have emerged. Let’s delve into the unique features of the three most common types.

### Types of Brushless Motors

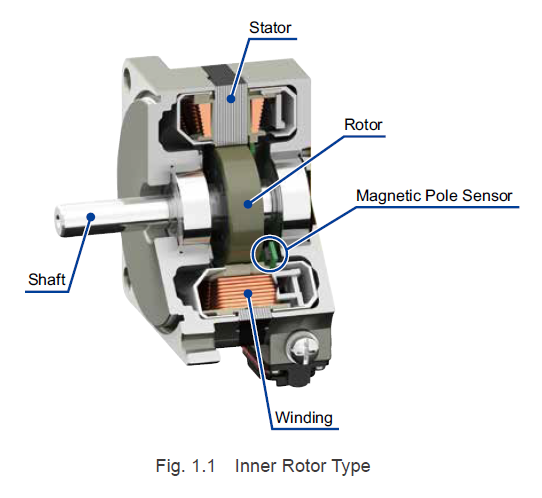

#### 1.1 Inner Rotor Type

The inner rotor type places the rotor within the stator, with segmented permanent magnets affixed to the outer surface of the rotor. Its small rotor diameter and low moment of inertia make it highly responsive for quick acceleration and deceleration. Additionally, the proximity of the stator to the motor surface enhances heat dissipation, enabling compact yet high-output motors.

This configuration is widely used in various applications, including conveyor systems and AGV (Automated Guided Vehicle) wheel drives. If you're looking for a motor that combines efficiency with space-saving capabilities, this type might be ideal for your material handling needs.

To better understand its functionality, take a look at this video demonstration:

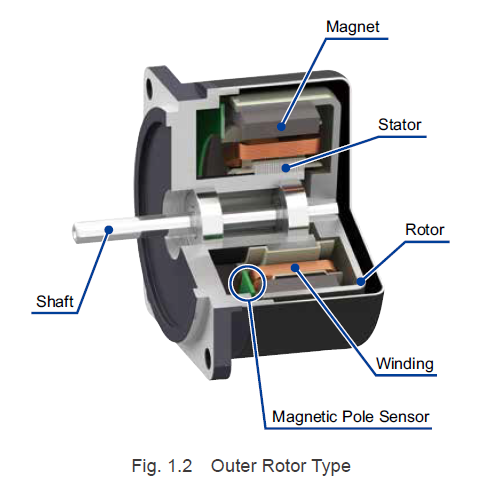

#### 1.2 Outer Rotor Type

In contrast to the inner rotor type, the outer rotor type positions the rotor outside the stator, with the permanent magnet located inside the rotor. This reverses the arrangement of the stator and magnets compared to the inner rotor type. Although the larger rotor diameter results in greater inertia, which affects quick starts and stops, it offers superior speed stability.

The larger rotor allows for more magnets, increasing the number of magnetic poles, which contributes to high output power in a compact form. However, the interior placement of the windings means poor heat dissipation, causing the windings to heat up quickly. This limits continuous operation unless measures such as ventilation or cooling are incorporated. For instance, drone motors often include ventilation holes in the rotor cup to enhance airflow and keep the windings cool.

While applications are somewhat restricted due to the challenges mentioned, the outer rotor type is still employed in cooling fans and drones. By optimizing thermal management, this motor can serve a broader range of uses.

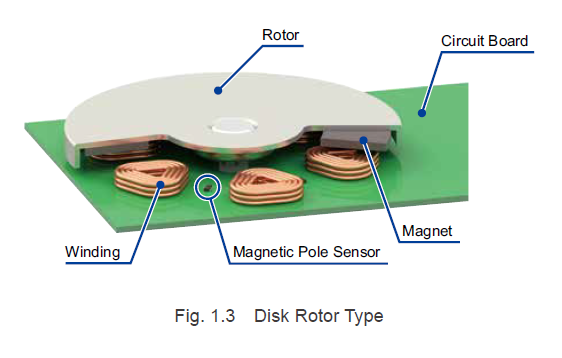

#### 1.3 Disk Rotor Type

The disk rotor type mounts the windings and magnetic pole sensors on the circuit board, with tabular permanent magnets positioned on the rotor facing the stator. This design creates a slim profile, making it suitable for maintaining stable, fixed speeds under light loads. Since there’s no shaft, the load is directly attached to the rotor.

Primarily utilized in hard disk drives and similar devices, this type is advantageous where space is constrained. Although Oriental Motor doesn’t offer disk rotor type motors, our brushless motors are uniquely designed to be shorter than competitors'. For positioning or indexing applications, we provide flat type stepper motors (42/60 mm frame sizes).

---

Stay tuned for the next installment of our Technical Manual Series, where we’ll explore brushed DC motors. Don’t miss out—subscribe to our blog to stay updated!

If you’re interested in learning more about Oriental Motor’s brushless motor solutions, feel free to reach out to our team! And don’t forget to check out our video below for insights into speed control innovations:

We hope this overview has provided valuable insights into the world of brushless motors. Whether you’re considering inner rotor, outer rotor, or disk rotor configurations, each type offers distinct advantages depending on your application requirements.

Thank you for reading, and remember to subscribe to our blog for more informative content!

Air To Air Heat Exchanger

A series of thin metal plates parallel to each other and pressed with a distance column are stacked to form a plate air-Air Heat Exchanger. The main components are heat transfer plates, outer frame sealing plates, compression device and so on.

The plate adopts full welding seal, flue gas and air cross flow between the plate for heat exchange. It`s suitable for air preheating and waste heat recovery in steel, chemical, electric power, battery and other industries, especially suitable for ultra-high temperature air to air heat exchange field.

Tranp`s Plate Air-Air Heat Exchanger is especially suitable for heat exchange between gas medium with high corrosion, high dust and high humidity.

The surface of the heat exchange plate is smooth with strong self-cleaning ability, so it is easy to clean. And multiple process is available, which is customized for different working conditions. Besides, the processing capacity can be as low as ten, but also as high as thousand CBM, therefore it`s widely used in waste heat recovery. What is more, the plate adopts advanced welding equipment and technology, combined use of resistance welding and manual welding between plates ensures that the weld joint is not easy to burst.

Air To Air Heat Exchanger,Air Preheater,Air Preheater In Boiler,Plate Type Air Heat Exchanger

Guangdong Jiema Energy Saving Technology Co.,Ltd , https://www.jmheatexchanger.com