Mechanical seals with multiple springs are available in a wide range of elastomers, making them suitable for handling virtually every industrial fluid. All components are held together by a snap ring in a unified construction design and can be easily repaired on-site.  High Quality Mechanical Seals John Crane 2100 Aesseal B05 seal Flowserve Pac-Seal 140 Sterling 540  Operating Conditions:  Temperature: -20°C to +120°C Pressure: ≤1.8MPa Speed: ≤15m/s Materials:  Stationary Ring: V1, Q1, Q2, U2 Rotary Ring: B, A, Q1, Q2 Secondary Seal: P, E, V Spring and Metal Parts: F, G Seat Types:  Standard: JRCT20-1 Alternative: JRT20, JRCT20, JRT21, JRT11 Applications: Clean water, sewage water, oil and other moderately corrosive fluids UHMWPE liner,Wear resistant UHMWPE liner plate,UHMWPE sheets,engineering plastics,HDPE liners Hebi Shuanglian Trading Co., Ltd. , https://www.slwearrubber.com

Description:

Â

These mechanical seals can be interchangeable with John Crane, Burgmann, Aesseal, Vulcan, Roten, and others. We offer a complete range of mechanical seals for Flygt Pumps, Grundfos Pumps, Alfa Laval Pumps, APV Pumps, Grindes Pumps, Fristam, ABS, Alleeiler, EMU, GEA Tunchenhagen, Godwin, Hidrostal, Hilge, Johnson, Lowara, Waukesha, Vogelsang Pumps, and more.

Additionally, we can manufacture seals according to your samples or drawings and design them as per your requirements.

As an advanced designer and manufacturer of mechanical seals, our product range includes: industrial pump mechanical seals, mixer and agitator seals, cartridge seals, metal bellows seals, auto cooling pump seals, and auto air-condition compressor lip seals.

They are widely used and highly reliable in industries such as food, beverage, petroleum, chemical, refinery, papermaking, pharmaceuticals, power, and automotive sectors.

Features include high and low temperature resistance, acid and alkali resistance, ozone resistance, aging resistance, weather resistance, good insulation properties, non-toxic, and good air permeability.

Welcome to contact us for more details.

Question 1: Are you a factory or a trade company?

Answer: We are a factory and have our own sales team for trade services.

Question 2: Can I get a sample before placing an order?

Answer: Yes, you can request samples. Usually, they are free of charge.

Question 3: Where is your factory located? How can I visit it?

Answer: Our factory is located in Ningbo, China. You can fly directly to Ningbo or Shanghai airport. All our clients, both local and international, are warmly welcome to visit us!

Question 4: How does your factory handle quality control?

Answer: Quality is our top priority. We take great importance in quality control from beginning to end. Our factory has obtained ISO9001 certification.

Question 5: What is the lead time?

Answer: Within 10-20 days after receiving the prepayment.

Question 6: What payment methods do you accept?

Answer: For small sample shipping costs, you can pay via PayPal or T/T. For larger orders, we accept T/T at sight.

Â

Question 7: Is OEM available?

Answer: Yes, we provide OEM/ODM services for all our products.

Â

Question 8: Can I buy pumps or pump parts from your company?

Answer: Yes, we also supply pumps and pump parts, such as lobe pumps, compound and homogeneous pumps, homogeneous and emulsification pumps, and more. Please visit our website: www.supseals.com

Mechanical Seal John Crane 2100

Model NO.: 210

Type: O-Ring Mechanical Seals

Balance: Balanced

Function: for Pump, Compressor

Certificate: ISO9001

Replacement to: Burgmann Seal

Trademark: JR

Transport Package: Carton

Specification: as requirement

Origin: China

HS Code: 848420090

Operating Conditions:

Temperature: -20°C to +120°C

Pressure: ≤1.0MPa

Speed: ≤15m/s

Materials: Stationary Ring: Ceramic (Alumina), Silicon Carbide Reaction Bonded, Silicon Carbide Sintered Pressureless, Ni-binder Tungsten Carbide

Rotary Ring: Resin Impregnated Carbon Graphite (Furan), Antimony Impreg. Carbon Graphite, Silicon Carbide Sintered Pressureless, Silicon Carbide Reaction Bonded Secondary Seal: Nitrile (NBR), Ethylene Propylene (EPDM), Fluorocarbon Rubber (Viton)

Spring and Metal Parts: Stainless Steel, Stainless Steel

Applications: Clean Water, Sewage Water, Oil and other moderately corrosive fluids.

Â

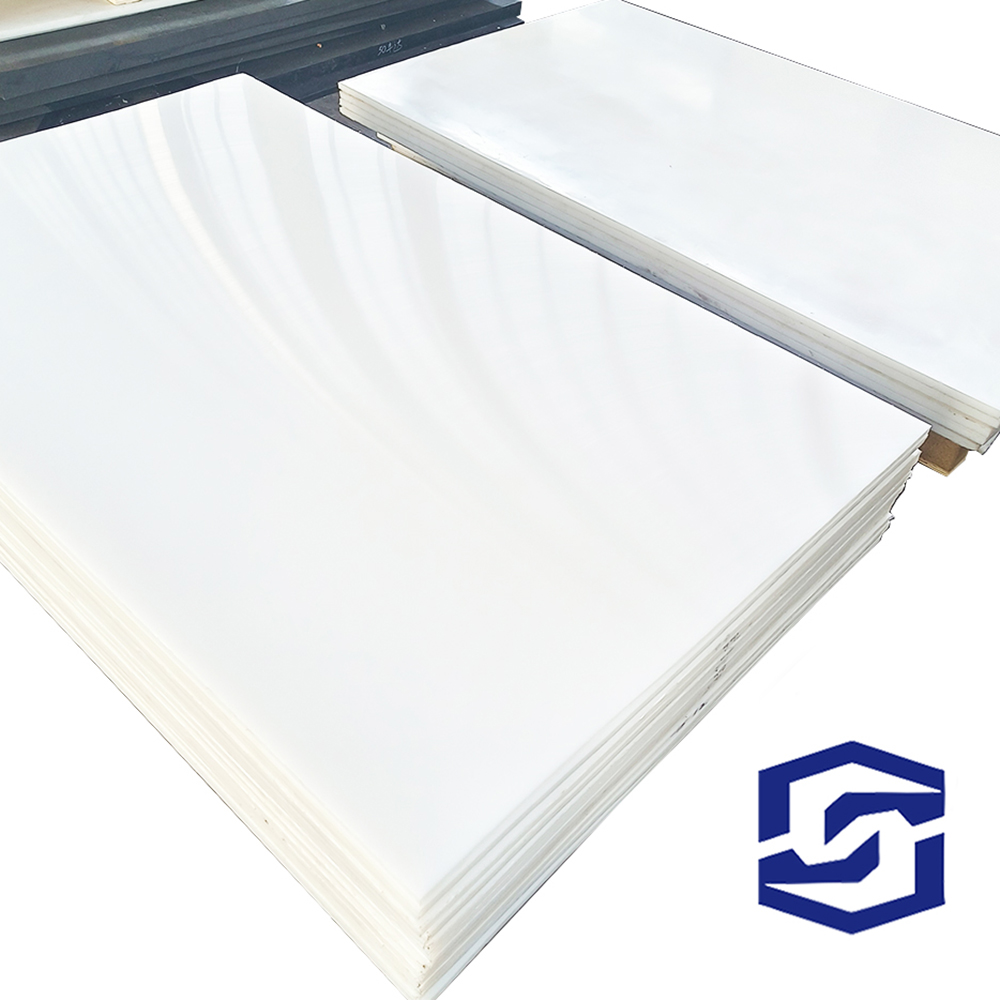

Ultra-high molecular weight polyethylene linerboard also known as UHMWPE liners, is a thermoplastic engineering plastics with molecular weight up to more than 3 million, it has good anti clogging, self-lubricating, non absorbent, high wear resistant, corrosion resistant, it has been widely used in coal, electric power, cement, metallurgy, and other industries in the raw coal silo, clay silo, iron silo, mixing silo, and other kinds of silos.

The product can completely solve the silo, hopper, mine chute, chute, storage boxes and other warehouse wall of the sticky material, stick to the wall, blocking material and other serious impact on the production of the problem.