The rise of electric mobility and EV battery production

With the growing trend of electric mobility, the demand for electric vehicles (EVs) has surged, which in turn drives the need for more EV batteries. This raises important questions about how manufacturers can meet this rising demand and what materials are essential for producing these batteries.

In this article, we take a closer look at the materials used in EV batteries, the manufacturing process, and the key players in the industry. We also explore the challenges posed by the increasing demand and what the future might hold for EV battery technology.

What are EV batteries made of?

EV batteries come in various shapes and sizes, from different cell formats to varying chemistries. Before diving into the materials used, it’s essential to understand the basic types of battery cell structures. These structures influence performance, cost, and overall design.

The different types of EV battery cells

There are three main types of battery cells used in electric vehicles: cylindrical, prismatic, and pouch cells. Coin cells exist but are mainly used for research purposes and not in commercial EVs.

1. Cylindrical Cells

Cylindrical cells are the most widely used format, similar to standard AA or AAA batteries. They are known for their durability and ease of manufacturing, making them cost-effective. However, they may have limitations in power output compared to other types.

2. Prismatic Cells

Prismatic cells are larger and can store more energy. Their design allows for better heat management and higher power output. Though less common than cylindrical cells, their use is on the rise and expected to grow in the coming years.

3. Pouch Cells

Pouch cells are encased in flexible plastic, offering efficient space usage. However, their soft casing requires additional protection to prevent damage during handling and use.

What materials are most popular to use for EV batteries?

Beyond their physical structure, EV batteries also differ based on their chemistry. The choice of materials affects performance, cost, and sustainability.

Lithium-ion (Li-ion) batteries are the most widely used due to their balance of cost and energy density. Other chemistries like Nickel Manganese Cobalt (NMC), Nickel Metal Hydride (Ni-MH), and even lead-acid batteries were once common in early EV models.

Lead-acid batteries, though older, are still used in some hybrid vehicles because they are easy to maintain and repair. However, they are not suitable for large EVs due to their limited energy storage capacity.

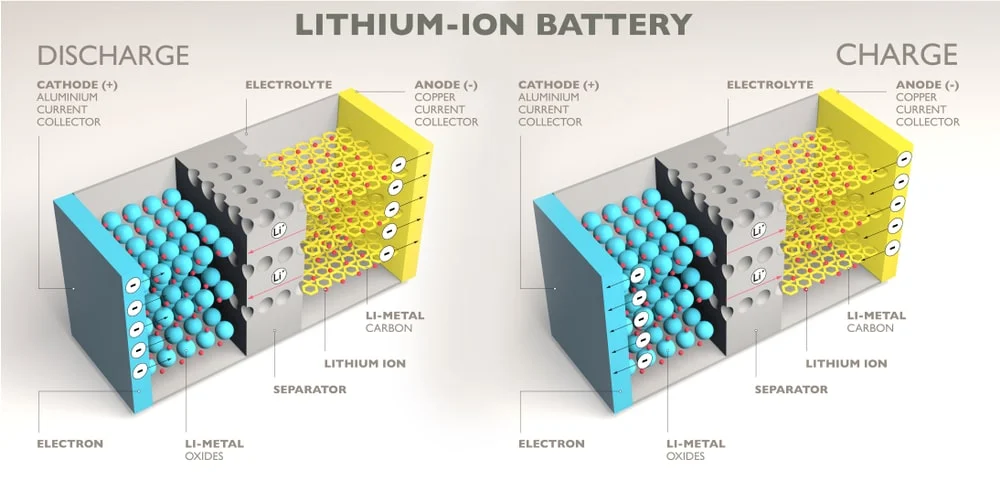

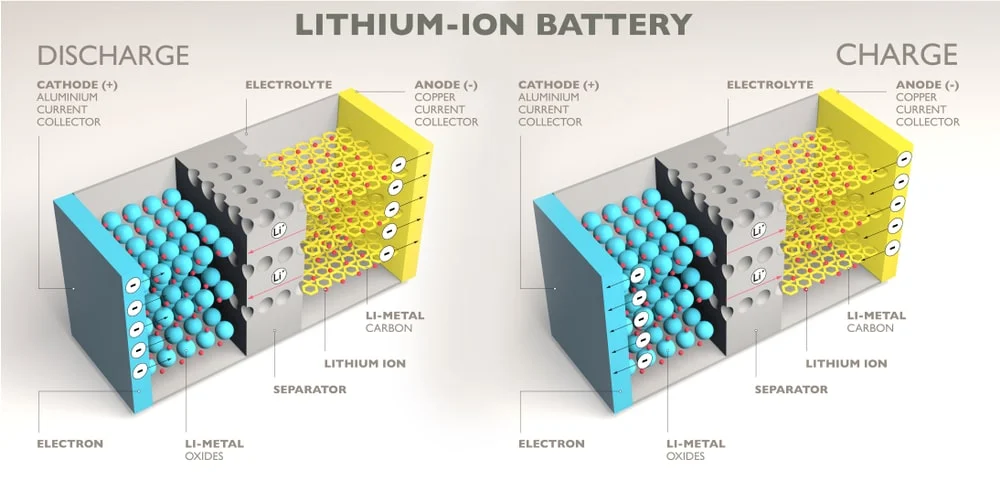

What are Lithium-ion batteries made of?

Lithium-ion batteries contain lithium, along with other elements such as nickel, cobalt, and manganese in the cathode, and graphite in the anode. These materials work together to store and release energy efficiently.

The individual cells are then enclosed in a protective casing—often made of aluminum or steel—to ensure safety and durability.

What are the components needed for the battery?

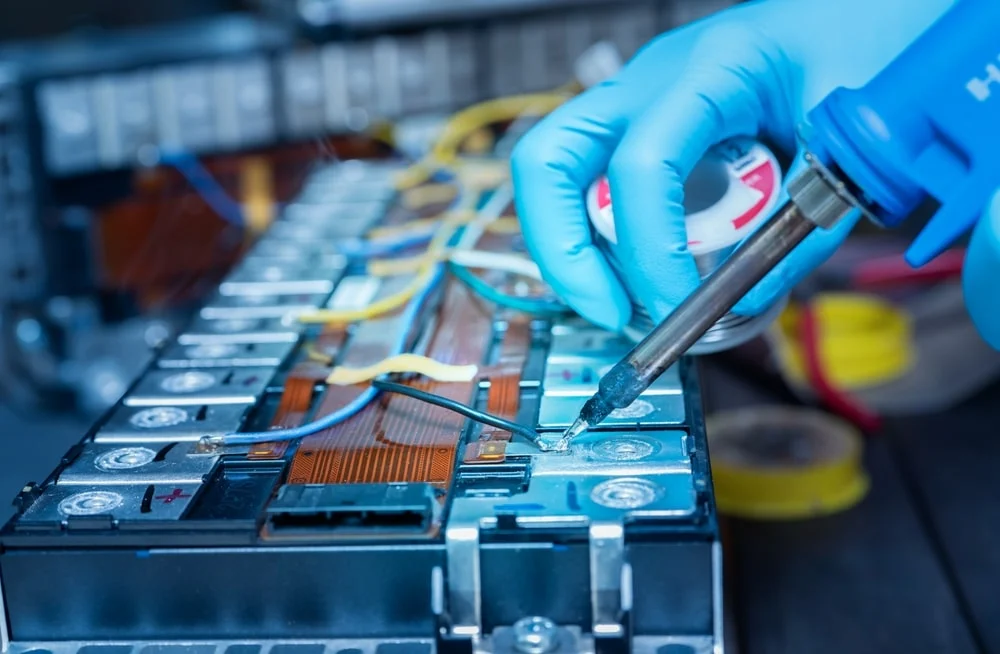

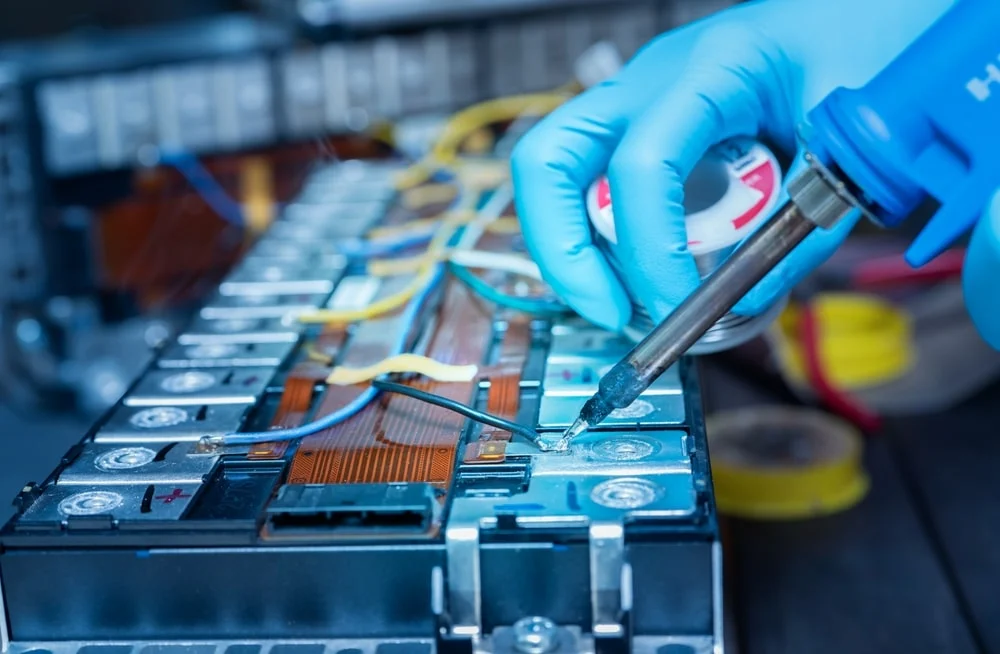

An EV battery isn’t just about the cells—it also includes several critical components that make it functional and safe.

Battery Module Array

This refers to the group of cells wired together to form a module, which then combines into the full battery pack. It's the core part responsible for energy storage.

Battery Management System

The Battery Management System (BMS) is crucial for monitoring and controlling the battery’s performance. It ensures optimal charging, discharging, and temperature regulation, helping to extend the battery’s lifespan.

Battery Electrical System

This system includes all wiring, fuses, and connections necessary for the battery to function properly. It works closely with the BMS to manage each cell efficiently.

Battery Cooling System

EV batteries generate heat, so a cooling system is essential to dissipate excess heat and maintain safe operating temperatures. This often involves a sealed coolant system that circulates around the cells.

Battery Protection Case

The protection case holds all the components together and must be airtight, waterproof, and resistant to shocks and vibrations. Its design is crucial for ensuring the battery’s safety and longevity.

Who manufactures them?

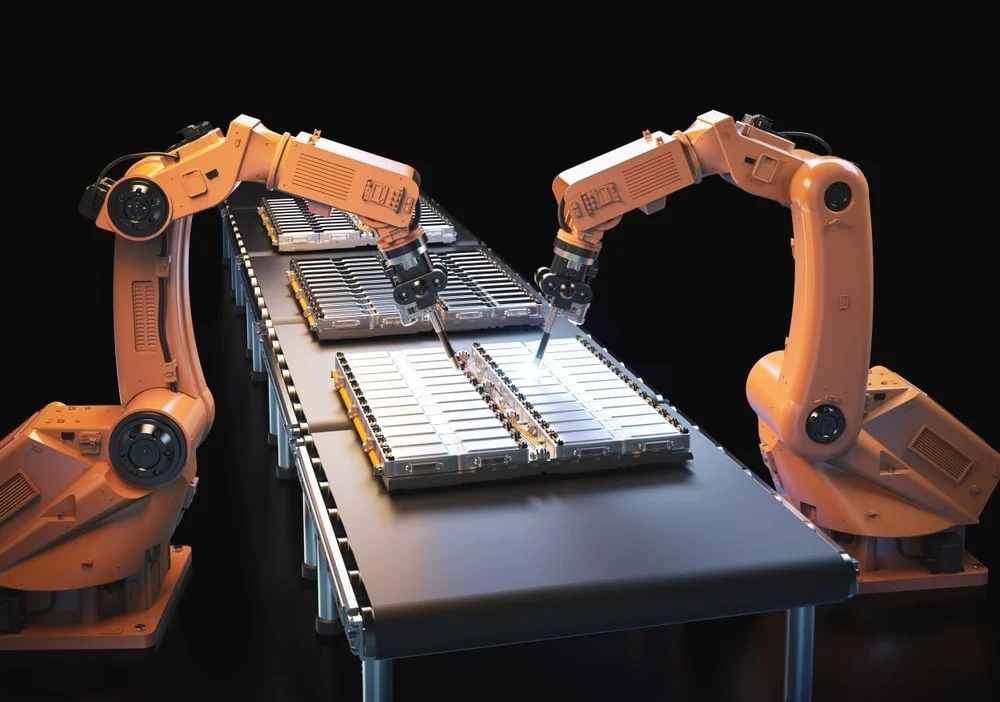

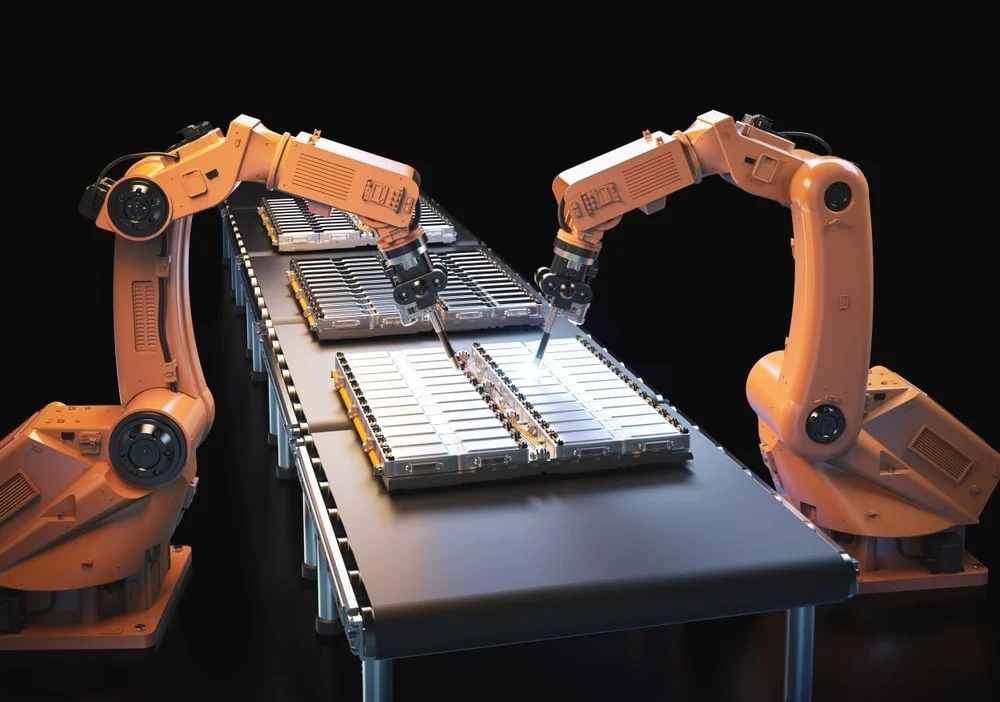

Due to the high costs and complexity involved, EV battery production is concentrated among a few major companies. The leading manufacturer is CATL (Contemporary Amperex Technology Co. Limited), holding around 34% of the market share.

China dominates the supply chain, with 70% of cathode production and 85% of anode production occurring there. Additionally, over half of the raw materials for EV batteries come from China.

Other top manufacturers include LG Energy Solution and BYD, with market shares of 14% and 12%, respectively. BYD is unique in that it also produces electric vehicles, allowing it to meet much of its own battery needs.

While the US, Japan, and South Korea contribute to the global market, China remains the dominant player in EV battery manufacturing.

Supply and demand gap

The rapid growth of electric mobility has led to challenges in sourcing raw materials for EV production, especially batteries.

Since 2020, the automotive sector has faced ongoing shortages of computer chips, impacting EV production costs. In addition, there are growing concerns about shortages of lithium and graphite, both essential for battery production.

Graphite is a key component of the anode, and shortages could drive up production costs further. This highlights the need for sustainable solutions and alternative materials.

The future of EV batteries

With rising material costs and supply chain issues, the future of EV batteries looks increasingly focused on sustainability and innovation.

One promising solution is battery recycling, which helps recover valuable minerals from old batteries and reduces the need for new raw materials. This not only addresses supply issues but also makes battery production more eco-friendly.

Additionally, ongoing research aims to improve battery efficiency, potentially reducing the amount of raw materials required. Combined with policy support for domestic production, these efforts should help keep EV batteries affordable and available in the long term.

EV battery manufacturing is complex and resource-intensive, but advancements in recycling, material science, and policy initiatives are paving the way for a more sustainable and accessible future. If you're interested in learning more, check out our articles on how much EV batteries cost or how they can be recycled.

Â