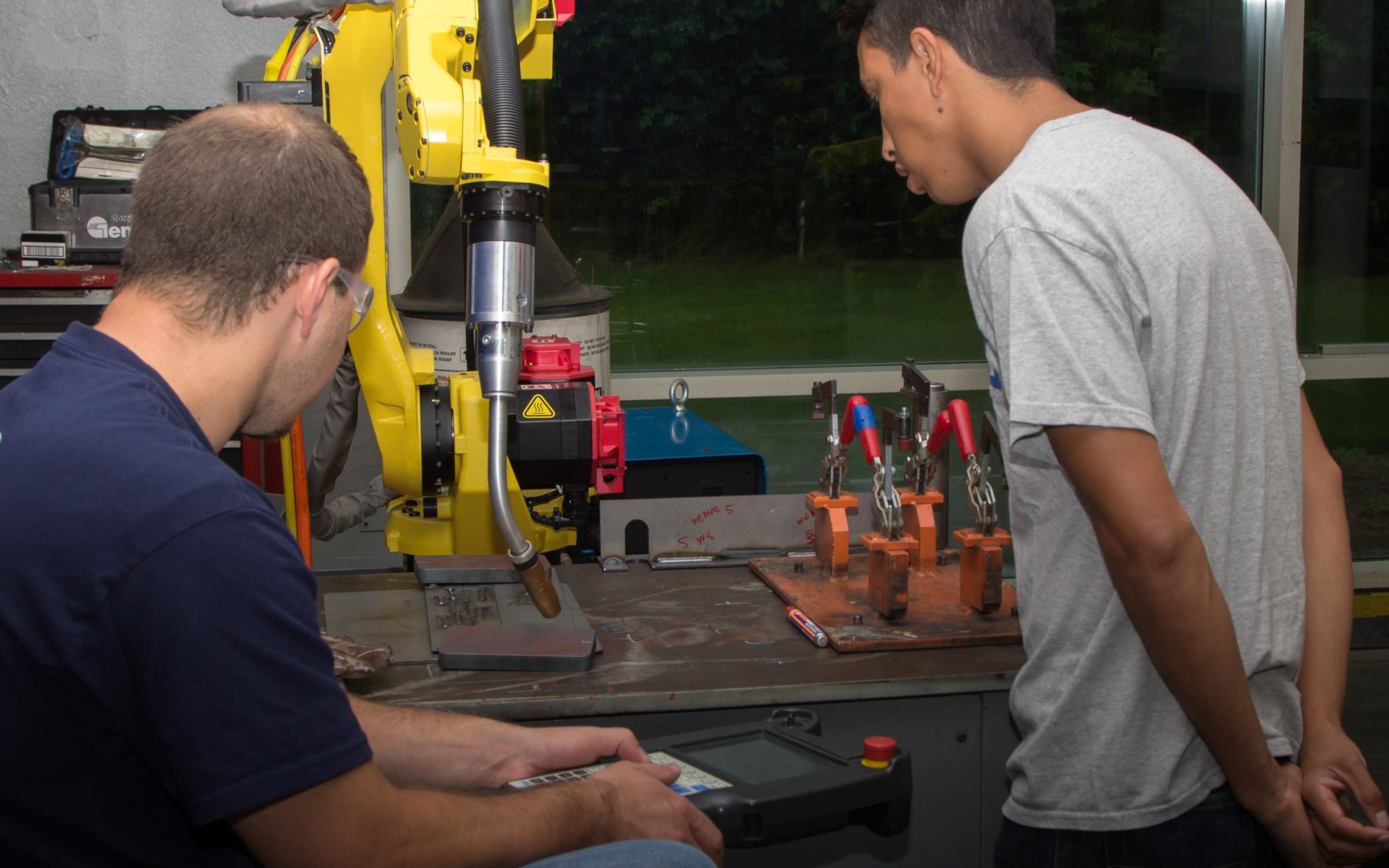

As robotics becomes more integrated into modern manufacturing and industrial environments, the need for skilled and well-trained robot operators has never been greater. Proper training ensures that these operators can handle complex robotic systems efficiently, safely, and with minimal downtime. Whether you're introducing new automation or upgrading existing systems, investing in operator training is a critical step toward long-term success. There are numerous robot training programs available from manufacturers, integrators, and educational institutions. Choosing the right program can make a big difference in how effectively your team can manage and maintain robotic operations. A well-structured training program not only enhances technical skills but also improves overall productivity and safety in the workplace. One of the most significant advantages of robot operator training is increased productivity. Trained operators are better equipped to handle new robotic systems, reducing the time it takes to get up to speed and minimizing costly delays. Additionally, they can quickly troubleshoot issues, which helps maintain consistent output and reduce unplanned downtime. Safety is another major benefit. Operators who receive proper training understand how to follow safety protocols, use protective equipment, and respond to emergencies. This leads to fewer accidents, lower liability, and a safer working environment for everyone involved. Training also helps maximize the return on investment (ROI) of your robotic systems. Skilled operators can optimize the performance of robotic cells, ensuring that machines run at peak efficiency. This not only increases output but also extends the lifespan of the equipment, providing long-term value for your business. Not all training programs are created equal. When selecting a program, look for one that offers hands-on experience with real robotic systems. Small class sizes allow for personalized attention, while practical exercises help reinforce theoretical knowledge. A good program should balance lecture time with actual robot operation, ideally around 20% theory and 80% hands-on practice. Another key factor is the expertise of the instructors. Ideally, the trainers should have years of experience working with various types of robots and programming languages. They should be able to tailor the course to the specific needs of your facility and your team’s skill level. Robot technology is constantly evolving, so ongoing education and training are essential. Encouraging continuous learning helps operators stay updated with the latest advancements, ensuring your robotic systems remain competitive and efficient over time. If you're looking for comprehensive and practical robot training, consider exploring options like Genesis Systems Group's hands-on courses. These programs provide real-world experience and are designed to help operators build confidence and competence in managing advanced robotic systems. Double Hoses Submersible Pump Type Fuel Dispenser ,Single Product Fuel Dispenser,Double Products Gear Pump Suction Fuel Dispenser,Diesel Double Hoses Fuel Dispenser Henan Wenjia Energy Technology Co., Ltd , https://www.hnwjny.comThe Importance of Proper Robot Operator Training

The Benefits of Robot Operator Training

What to Look for in a Robot Training Program

The Importance of Proper Robot Operator Training

The Double Hoses Fuel Dispenser is a versatile and efficient solution designed for fuel stations that require flexible dispensing options for multiple fuel types or faster service throughput. Equipped with two dispensing hoses—either for a single product with dual nozzles or for two separate fuel products—this configuration enhances operational efficiency while optimizing space on the fueling island.

Â

Built with durable materials, high-accuracy flow meters, and user-friendly controls, the double hose model is suitable for a wide range of applications, from retail gas stations to commercial and fleet fueling sites. It supports standard fuel types including gasoline, diesel, and biodiesel, and can be customized with either mechanical or electronic metering systems to match the needs of various service environments.

Â

As part of a modern gas station equipment lineup, the double hoses fuel dispenser integrates easily with POS systems, fleet card readers, and remote management platforms, offering both performance and convenience in one complete solution.

Â

Key Features:

• Two hoses for increased fueling flexibility

• Supports single or dual product dispensing

• High-precision metering system (mechanical or electronic)

• Durable, weather-resistant construction

• Clear LED or LCD display for real-time transaction info

• Seamless integration with station control systems (RS-485, TCP/IP)

• Optional configurations: suction or submersible pump type

• Compatible with gasoline, diesel, and biofuel blends

Â

Applications:

• Retail gas stations with medium to high traffic

• Fleet fueling stations requiring fast multi-vehicle service

• Highway service areas

• Industrial and agricultural fueling depots

Â

The Double Hoses Fuel Dispenser offers the perfect balance of functionality, reliability, and adaptability—making it a smart choice for fuel stations looking to improve service speed and fuel management capabilities.