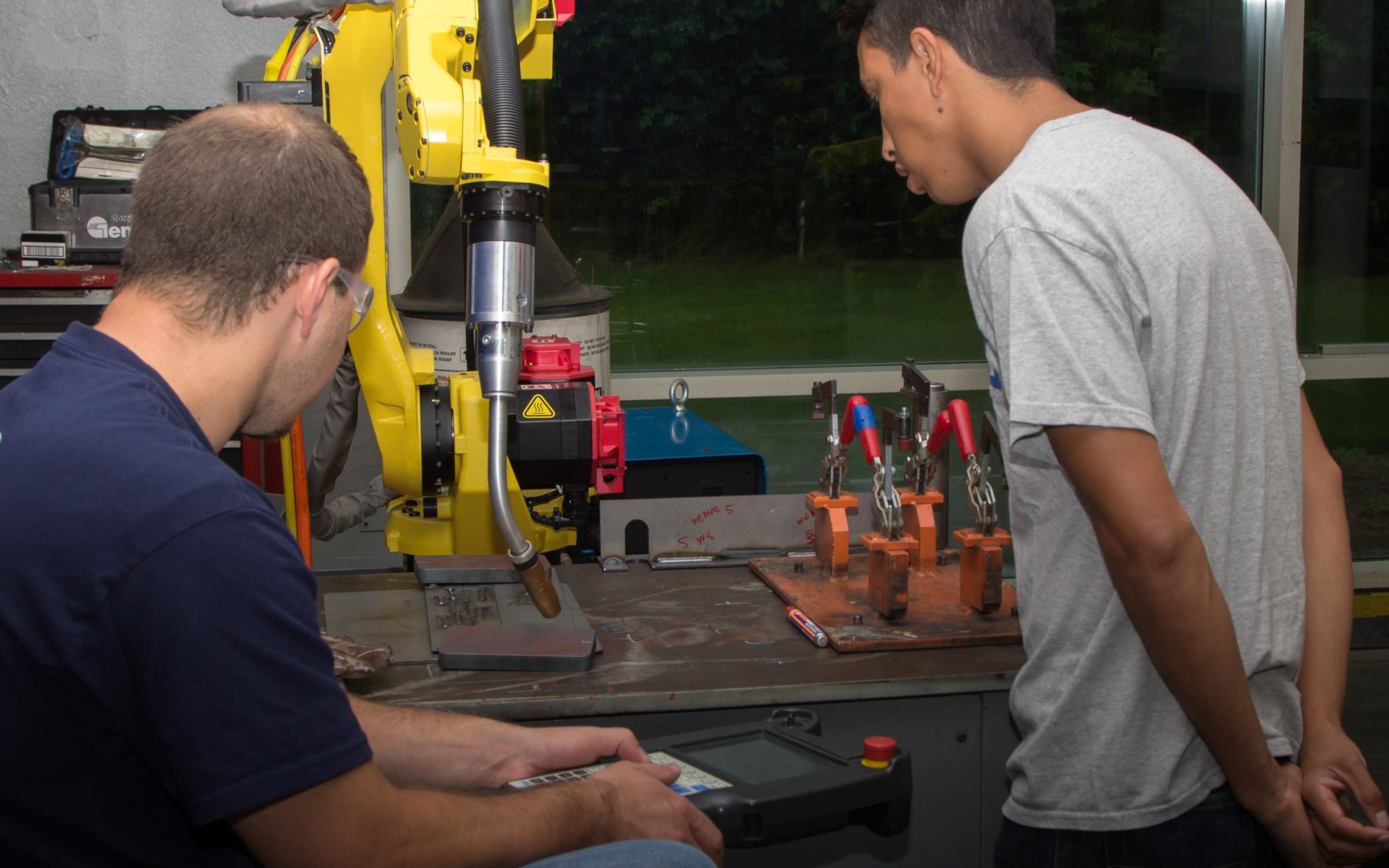

Introducing robotic automation into a facility is a major step that requires skilled and well-trained operators to ensure smooth operations and maximum efficiency. Proper robot operator training is not just a formality—it’s a critical component of maintaining high productivity and minimizing downtime. As technology evolves, it's essential for operators to stay updated with the latest systems, programming techniques, and best practices. There are numerous robot training programs available, and many integrators offer their own. Choosing the right program can make a significant difference in how effectively your team operates. Well-trained operators bring more value to your organization, leading to better performance and long-term cost savings. One of the most immediate benefits of robot training is increased productivity. When new robotic systems are implemented, trained operators can adapt quickly, reducing the learning curve and associated downtime. This helps keep production moving without unnecessary delays. Safety is another key aspect of robot training. Operators who understand safety protocols and best practices are less likely to cause accidents or injuries, which in turn reduces downtime and potential legal issues. A well-trained workforce contributes to a safer, more efficient working environment. Robot training also enhances the return on investment (ROI) of your robotic systems. Trained operators can optimize the performance of the robots, ensuring they run at peak efficiency. They are better equipped to troubleshoot problems, perform routine maintenance, and make adjustments that improve overall system performance. With so many training options available, it's important to choose a program that offers real value. Look for courses that provide hands-on experience, as this is where most of the learning takes place. Ideally, a good program should have small class sizes, allowing for personalized attention and more time working directly with robotic systems. A strong training program should include around 20% lecture and 80% practical, hands-on work. This approach ensures that trainees gain real-world skills that they can apply immediately in their jobs. Additionally, the instructors should be experienced professionals with a deep understanding of various robotic systems and programming languages. Continuous learning is vital in the fast-paced world of robotics. The right training program equips operators with the knowledge and confidence to handle new technologies and challenges. It empowers them to maintain high productivity and contribute to the success of the entire operation. If you're looking for quality robot training, consider exploring Genesis Systems Group’s comprehensive and hands-on training programs. These courses are designed to help operators master the latest robotic technologies and enhance their skills in a real-world setting. Six Hoses Three Products Fuel Dispenser,Eight Hoses Gear Pump Suction Fuel Dispenser,Four Products Fuel Dispenser,Four Products Submersible Pump Type Fuel Dispenser Henan Wenjia Energy Technology Co., Ltd , https://www.hnwjny.comThe Importance of Proper Robot Operator Training

The Benefits of Robot Operator Training

What to Look for in a Robot Training Program

The Importance of Proper Robot Operator Training

T9 Fuel Dispenser – Classification Overview

Â

The T9 Fuel Dispenser Series represents a new generation of high-performance dispensing solutions designed for accuracy, durability, and user-friendly operation. With a modern appearance and advanced internal systems, the T9 series is suitable for both retail and commercial fueling environments. These dispensers can be classified based on fueling capacity, nozzle configuration, control technology, and target application.

Â

1. By Fueling Capacity:

• Standard Flow Models (50–60L/min):

Suitable for passenger vehicles and daily retail fueling stations.

• High Flow Models (70–90L/min):

Ideal for light commercial vehicles and medium fleet stations.

• Ultra High Flow Models (≥120L/min):

Designed for trucks, buses, and industrial machinery requiring fast, high-volume fueling.

Â

2. By Nozzle Configuration:

• Single Nozzle:

Dispenses one fuel grade. Best for stations with limited space or simple fuel needs.

• Dual Nozzle:

Enables the dispensing of two fuel types or simultaneous service for two vehicles.

• Four Nozzle:

Suitable for high-traffic stations offering multiple fuel grades.

Â

3. By Control Technology:

• Mechanical Display Units:

Cost-effective, rugged design suitable for remote or budget-sensitive areas.

• Digital Display Units:

Feature clear LCD or LED screens, offering precise data and improved customer experience.

• Smart Dispensers:

Integrated with POS systems, IC card readers, and remote diagnostics for full automation and monitoring.

Â

4. By Application:

• Retail Fuel Stations:

Designed for efficiency, safety, and customer-friendly operation.

• Commercial Fleets:

Built for internal fueling systems with high accuracy and robust components.

• Mixed-Use Installations:

Adaptable for both retail and private use, depending on configuration.

Â

All T9 fuel dispensers are manufactured with corrosion-resistant materials, accurate metering systems, and advanced leak prevention features, ensuring long-term performance and minimal maintenance.