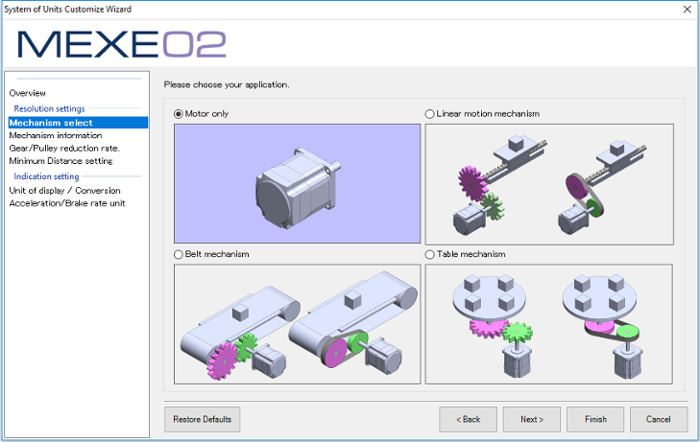

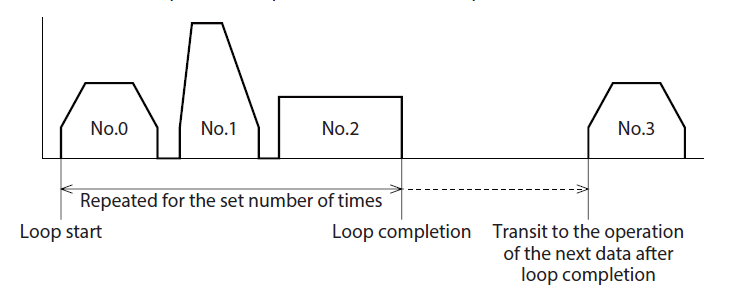

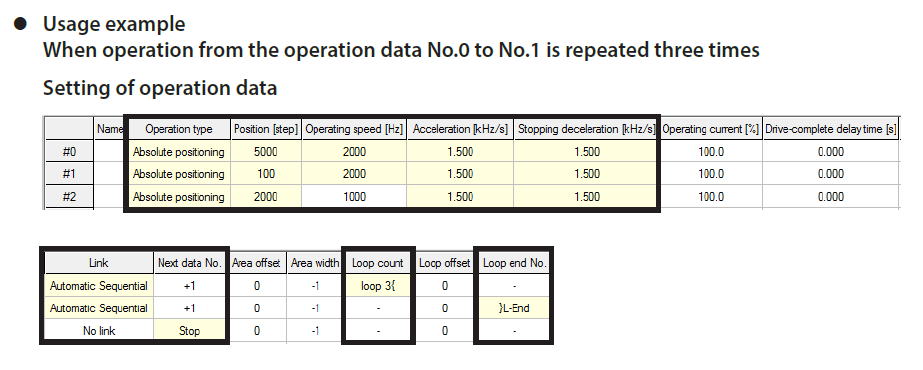

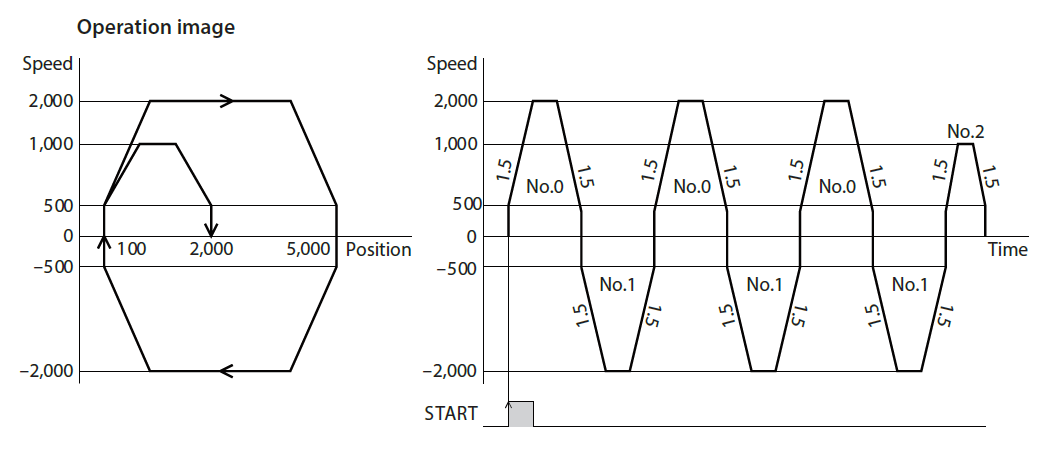

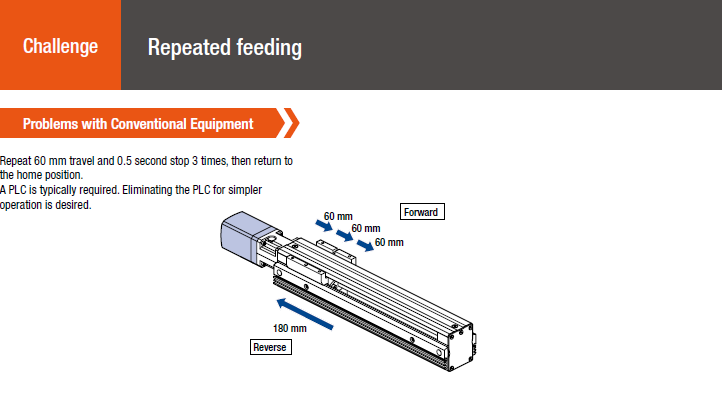

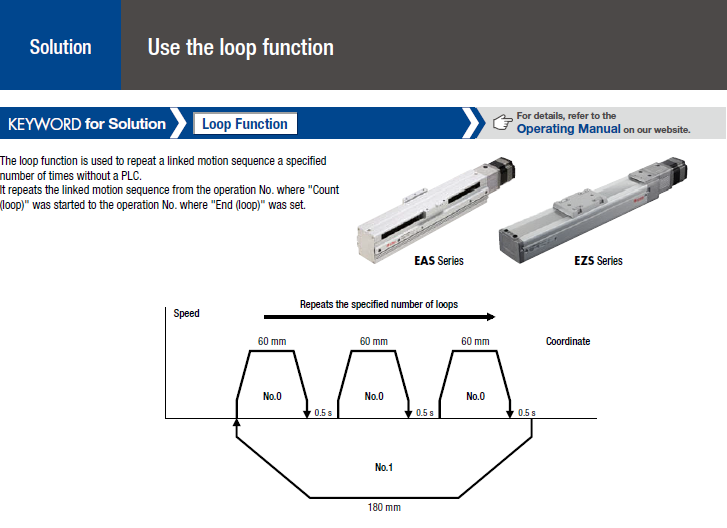

No matter how many features a product offers, without an intuitive and easy-to-use software, those features can be challenging to implement effectively. Oriental Motor simplifies things for their customers by providing a universal MEXE02 support software that works across multiple product series. Given that each product has different capabilities, the software adapts its format accordingly. By maintaining a consistent user interface across various products, the time needed to program motion sequences for each axis can be significantly reduced. The loop function is accessible when any AZ series product is paired with the MEXE02 software. For an overview of the software, check out this blog post or click on the image below. The Loop Function One of the most common motion sequences for stepper motors involves repeating the same movement over a fixed distance and in the same direction every time. In programming terminology, this is often referred to as a loop subroutine, meaning that any set of instructions contained within the loop subroutine will be executed repeatedly, either indefinitely or until a specific condition is met. Once the loop finishes, it returns to the main program. The following excerpt is from the AZ series functions manual. The loop function is a function to repeat the operation of the linked operation data number for the number of times set. Operation is repeated from the operation data number for which "Loop count" is set to the operation data number to which "Loop end number" is set for the number of times set in the "Loop count." When the operation for the number of times set is completed, the operation transits to the operation data number that is set to "Next data number". In essence, a loop function repeats the same movement by the number of times you specify. This is particularly useful for applications that require the same fixed distance every time, such as paper or ticket feeding or rotary indexing tables. Application Example: Let’s consider a robotic arm performing a dance routine every time someone walks by. For this application, you could use an AZ motor for the arm rotation joints, link three different moves together (No.0, No.1, No.2) sequentially, loop them for a specified number of times, and then move onto the next data set (No.3), finally holding that pose. Here's what we want to accomplish: This is how we program it... Check out the usage example below to see how this motion sequence is programmed on the MEXE02 software. Notice that only three data sets (#0, #1, #2) are needed for this motion sequence. A key benefit of the MEXE02 software is that once a move is programmed and stored, it doesn’t need to be reprogrammed. The secret lies in the second image showing "Next data No.", "Loop count", and "Loop end No." This tells the software how to execute data sets #0, #1, and #2. And voilà ! You’re done (don’t forget to save). Here's what the motion looks like when plotted on a chart. The Case for More Driver Intelligence Traditional stepper motor drivers are fairly basic, simply converting pulse commands into motor movement. The real intelligence is usually found in the host controller, such as a PLC, where complex motions can be achieved using ladder logic and pulse outputs. The advantage of using an AZ series driver is its advanced motion sequence programming, allowing the AZ series driver to operate without a PLC in certain scenarios. Various types of drivers are available for different purposes, such as pulse input, stored data, and multi-axis operations. Up to 256 "moves" can be programmed and stored in the driver's non-volatile memory. Even more "moves" can be achieved by using fieldbus communication protocols like Modbus RTU, EtherNet/IP, or EtherCAT. Advantages of Stored Data Programming By eliminating the need for a PLC, more space is saved, and the design becomes simpler. At the very least, the AZ series drivers should ease the burden on the host controller, meaning that a less costly PLC or HMI can be used. Since the AZ series motors come with built-in mechanical absolute encoders, external encoders, batteries, and sensors are unnecessary. Here's another application example featuring a linear slide.  Prefer to watch and learn? Here's a video to show you how it’s done.  For more information about the AZ series family of motors, actuators, and drivers, please click below. The same dedicated drivers and the same MEXE02 software are used with all of these products. Please subscribe!  1 inch 25mm wide different length highly visible straps with reinforced edges, Small Ratchet Straps,Tie Down Straps,Ratchet Strap Pulley,Mini Ratchet Straps,Tire Tie Down Straps WINNERLIFTING SAFETY EQUIPMENT CO., LTD. , https://www.winnerstrap.com hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'e351278a-3f10-4402-bda5-5b8829eac7d0', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'e351278a-3f10-4402-bda5-5b8829eac7d0', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '3257c162-1fd0-4923-a205-57699545d6e5', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, '3257c162-1fd0-4923-a205-57699545d6e5', {"useNewLoader":"true","region":"na1"});  hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'c9cd6ed1-0aa4-4485-aba4-c8a4b3128d90', {"useNewLoader":"true","region":"na1"});

hbspt.cta._relativeUrls=true;hbspt.cta.load(2284573, 'c9cd6ed1-0aa4-4485-aba4-c8a4b3128d90', {"useNewLoader":"true","region":"na1"});

Various models of hooks - For a non-marring hold, protecting your cargo and vehicle

Durable- Ratcheting component adjusts the straps from 1ft. to 16 ft. in length to easily and safely secure cargo

LOAD LIMIT - Safe working load limit of 1,100 lbs / break strength of 3,300 lbs

Motion Programming Example: Loop Function For Repeated Motion

1 inch 25mm wide different length highly visible straps with reinforced edges, Small Ratchet Straps,Tie Down Straps,Ratchet Strap Pulley,Mini Ratchet Straps,Tire Tie Down Straps WINNERLIFTING SAFETY EQUIPMENT CO., LTD. , https://www.winnerstrap.com

Various models of hooks - For a non-marring hold, protecting your cargo and vehicle

Durable- Ratcheting component adjusts the straps from 1ft. to 16 ft. in length to easily and safely secure cargo

LOAD LIMIT - Safe working load limit of 1,100 lbs / break strength of 3,300 lbs